I worked on a commercial job last year where we had to build an office that included a 42-in. tall, 5-ft. long wing wall. The wall was built out of metal studs, covered with drywall and finished along its top with a wood cap. The wall was held at one end by a bearing wall, but the only anchors holding the rest of the wall were the powder-actuated fasteners driven through the track into the slab. This had me worried. I was sure that, in time, people leaning on the wall would eventually weaken it to the point of collapse. So I strengthened the wall with concrete.

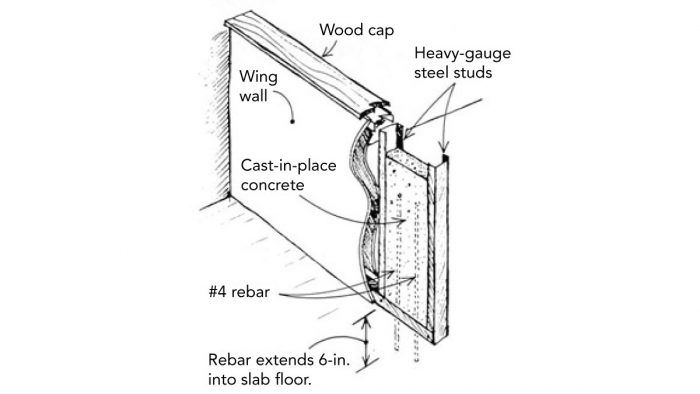

First I drilled a couple of 1/2-in. dia. holes through the track and 6 in. into the slab for a pair of #4 rebar. As shown in the drawing, I placed them in the outermost bay of the wall. I used heavy-gauge steel studs for the two outer studs and turned them so that the flanges faced each other to lock into the concrete better. Then I screwed some scrap 5/8-in. plywood to the two studs, making a 3-ft. tall form. Filled with concrete, the end of the wall became a cantilevered beam that is quite strong. The drywallers glued the drywall to the concrete, and we were done.

—Chris Sturm, Hamburg, PA

Edited and illustrated by Charles Miller

From Fine Homebuilding #82

View Comments

These are the kind of things I love to find when I'm doing a demo job.

That's why Jesus invented the 12 pound sledge.

It's a 1 cubic foot of concrete, that wouldn't slow me down at all doing demo...

We use a metal fence post with flange, purchased from your local bog orange box, and anchor them to the slab, Voila....stiff pony wall. More than one if the length is excessive.

I have accomplished the same thing by epoxying an all thread into the concrete and the using a hold down (HDU2) on double studs or a 4x4 at the end of the wall. Its much quicker and easier.