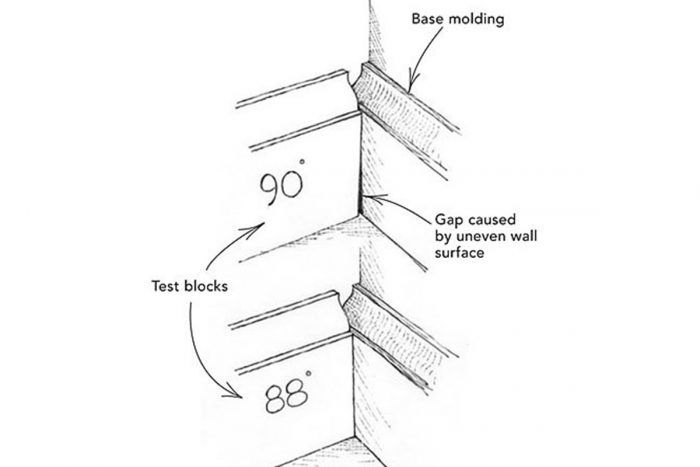

I do the finish trim work for a small builder of moderately priced homes in Norfolk, Va. He has found that it is actually less expensive to have the walls plastered than to have drywall hung, taped, sanded, and painted. Because plaster is a hand-tooled product, the walls are a little uneven, and the base moldings rarely end up plumb. As a consequence, I’ve learned that to keep the cope joints tight, the 45° bevel needs to be cut at a small angle off square, usually between 88° and 92°.

When I first started coping these joints, I used a bevel gauge to measure each angle, and then I’d adjust the compound-miter saw accordingly. That just took too long. I now cut five test blocks of base molding with miter angles ranging between 88° and 92°, in 1° increments. As shown in the drawing, I test-fit a couple of blocks to get the correct angle. Then I read the angle marked on the block, set the saw to that number, and I’m ready to cut. No more fussy fiddling.

—Dennis Smith , Suffolk, VA

Edited and Illustrated by Charles Miller

From Fine Homebuilding #170

View Comments

For moderately priced homes I miter the baseboard, inside and out, caulk it, and caulk the 1/16" -1/8" gap butt joint. Yes, it's fine homebuilding.

Huskiedad, that is not fine homebuilding where I come from.As to the original tip, I guess most of the baseboard installed is the same from house to house , so the gauge blocks could be reused from job to job or made from flat stock and reused