What’s the Difference: Fire-Resistant Drywall

Type X and type C drywall are designed specifically to be used in fire-rated assemblies.

Although all drywall is fire resistant to a degree, type-X and type-C drywall are designed specifically to be used in fire-rated assemblies. These products help to contain fire in the area of its origin much better than regular drywall. When this drywall is installed properly, it delays flames and heat from spreading around rooms, floors, and buildings, and it protects structural supports long enough for occupants to escape and for buildings to be saved.

Gypsum is noncombustible

The gypsum used to make drywall is a naturally occurring mineral composed of calcium sulfate dehydrate and water. The presence of water in gypsum contributes greatly to drywall’s natural fire resistance. When a drywall panel is subjected to high levels of heat, water begins to be released from the board as steam. This process, known as calcination, helps to retard heat transmission through the panel.

Once all the water has escaped the panel, the drywall continues to act as a fire barrier. When regular drywall is subjected to excessive heat, however, it shrinks due to the loss of water volume, and the panel can crack and fall apart. This type of failure permits the passage of fire and heat into the substrate material and beyond.

The cost difference

The cost difference between type-X and type-C fire-resistant drywall is small, only a few cents per square foot. Expect to pay around $11 for a 5/8-in.-thick 4-ft. by 8-ft. type-X sheet and $12 for a sheet of type C with the same dimensions.

Type X has good structural properties

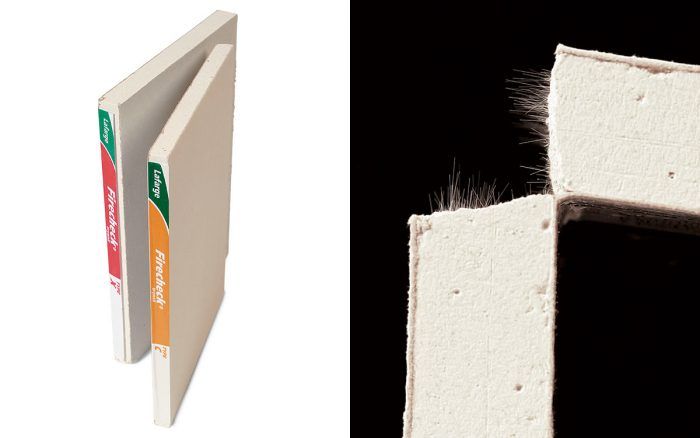

To make drywall stronger under fire conditions, manufacturers make type-X drywall, which has glass fibers added to its gypsum core. As water leaves these panels through calcination, the glass fibers act as a reinforcing mat that prolongs a panel’s structural integrity and its protective qualities.

Type-X drywall is available only in 5/8-in. thickness, in widths of 48 in. and 54 in., and in lengths up to 16 ft. Type-X drywall meets ASTM International standards and is often used in fire-rated assemblies such as walls and ceilings that separate garages from living spaces.

Installation notes

Type X and type C are installed like regular drywall. Although their fire-resistant qualities are greater than regular drywall, these products are scored, snapped, and finished like standard panels.

Type C is superior in performance

Type-C drywall is basically an improved type-X product. Typically, type-C panels contain more glass fibers as well as another noncombustible material: vermiculite. A mineral, vermiculite expands as it’s heated, so in fire conditions, it effectively replaces water lost during calcination. This reduces panel shrinkage and helps to maintain strength and durability.

Type-C drywall is available in the same lengths and widths as type-X drywall and in thicknesses of 1/2 in. and 5/8 in. Type-C drywall exceeds ASTM standards and can endure a blaze longer than type-X drywall. It’s often used in large buildings, such as multifamily-housing units.

Photos by: Krysta S. Doerfler