PROJECT HOUSE LINKS:

| HOME | BLOG | GALLERY | DETAILS | Q&A |

We’re about ready to begin the serious work of setting up the garage shop at the Project House. We have replaced the overhead door with new carriage house doors, insulated and hung drywall, replaced the windows and added a subfloor.

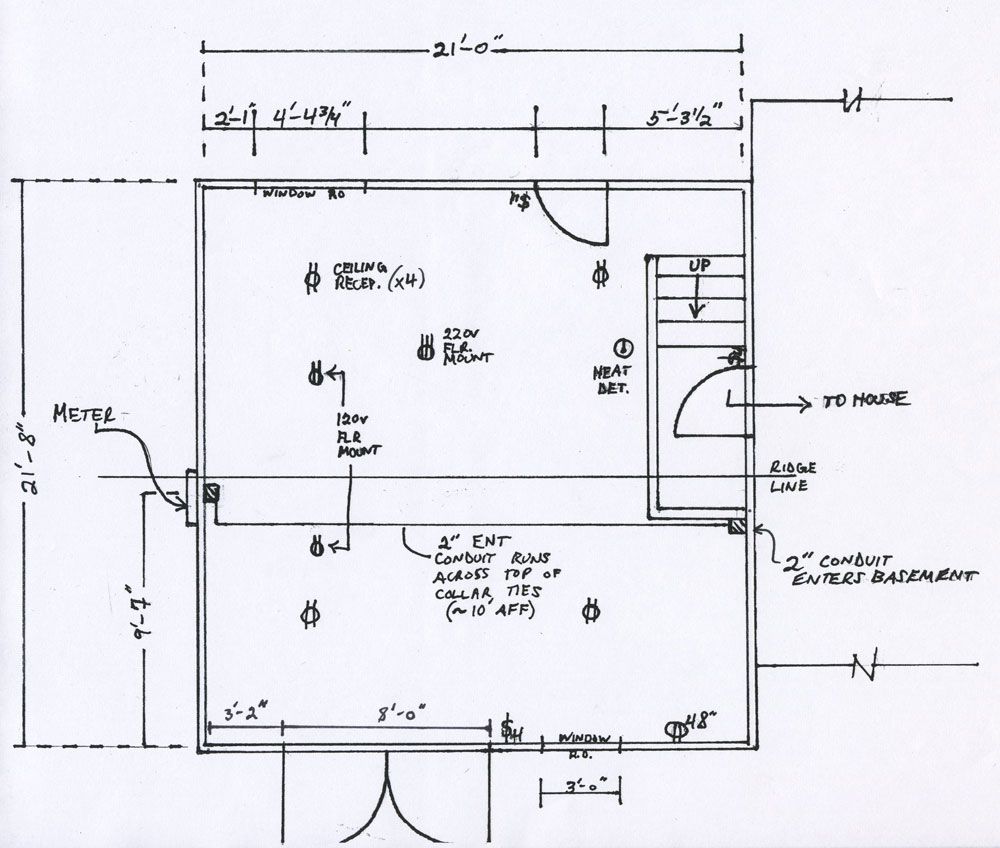

And we added a subpanel to power the shop along with benchtop-height outlets and ceiling outlets for lights.

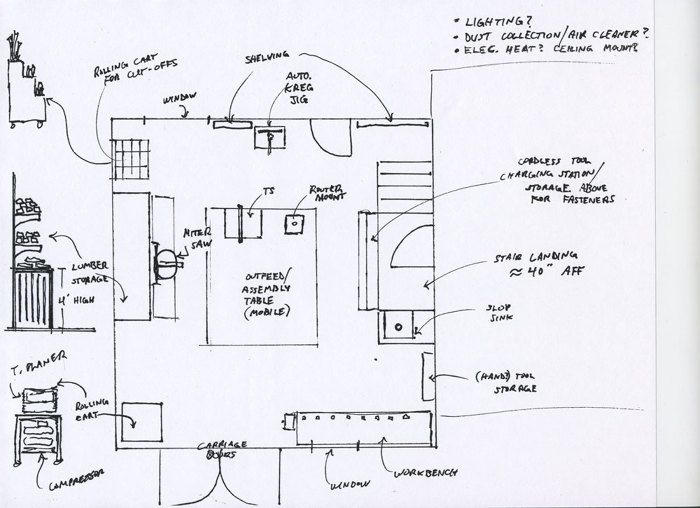

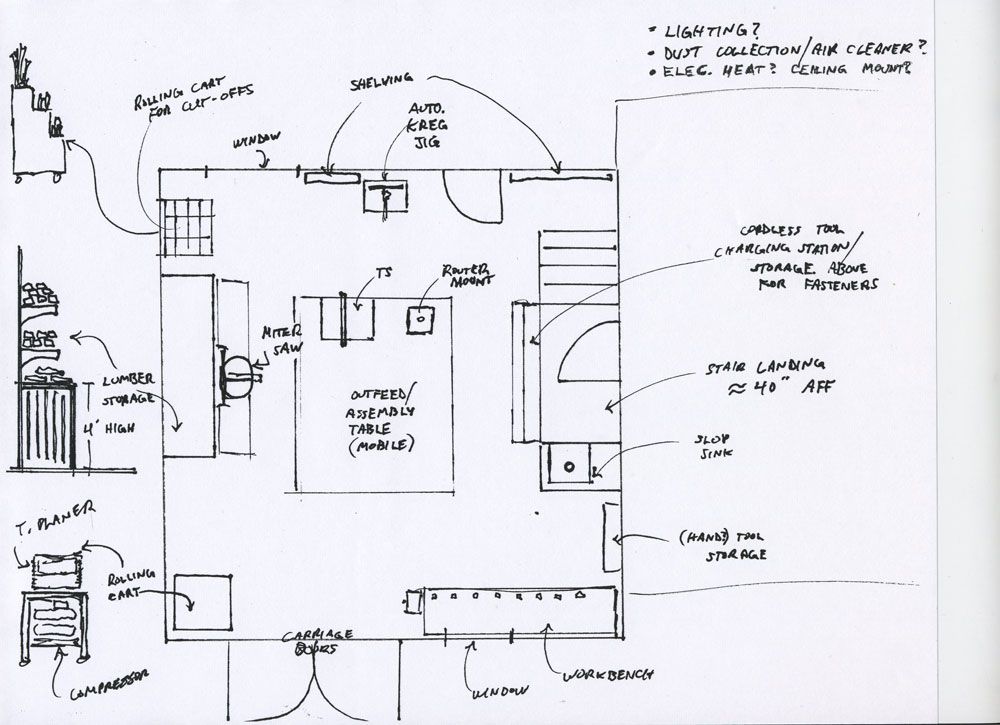

Above is our rough floor plan and electrical plan.

In general we’re looking for tips on setting up a remodeler’s shop. Ladder and cord storage, lumber racks, tool storage, compressors for sho[p use/compressors for moving to jobsites, etc.

When I was a migrant carpenter living in rentals and setting up my own garage shops, I used to try to follow a workflow for cabinet making: back up my truck to the door, slide plywood off the tailgate and onto the table saw. The outfeed table fed the miter saw station to cut parts to length. Parts were then assembled on a table towards the back, and a finishing room all the way back was one workflow design I tried to get to.

The spaces next to the overhead door were used for long skinny tools, like digging bars, long bar clamps, etc. and cords usually hung on a wall towards those front corners. Ladder storage could be difficult depending on the shop — some of the compact garages I set up (rentals) affirded little extra room for bulky stuff like that.

Tips?

Techniques?

Tactical advice?

PROJECT HOUSE LINKS:

| PROJECT HOUSE HOME | BLOG | PHOTO GALLERY | DETAIL DRAWINGS | Q&A FORUM |

Fine Homebuilding Recommended Products

Fine Homebuilding receives a commission for items purchased through links on this site, including Amazon Associates and other affiliate advertising programs.

Affordable IR Camera

Reliable Crimp Connectors

8067 All-Weather Flashing Tape

View Comments

Almost identical endeavor when moving my shop back to a smaller, more convenient location earlier this year:

https://picasaweb.google.com/111355467778981859077/EWoodShopRetrofit2011#5661590406311300114

I do miss the 200 square I gave up for "convenience" and ready access, but since I do rent additional storage space on an as needed basis for kitchen jobs and larger remodels, it works better than the small size indicates.

Great looking shop, swingman. I like the two closets which form a built-in bench. And the judicious use of French cleats.

Did you make the drawings in Sketchup?

@Swingman... very nice shop, thanks for sharing with everyone.

@DanMorrison... I am a remodeler and have a shop too. While my shop is in my garage, I did plan and build the 24x24 garage special to serve as a shop. After doing so, I found there were a few things I would do differently.

For starters, I wanted to allow for lots of light, access, and air flow so I put in 4 good sized windows, as well as a glazed access door to the house and another to the outside; then of course there is the two 10' wide roll up doors. The result is good light/air/access but very limited wall and storage space. It's a big trade off that I am not sure is worth it or not but certainly something to consider.

Next, I planned my outlet layout based on where the windows and doors were as well as where I expected to place a few machines. Well, sure enough it's all wrong (almost). Not long after I moved into the shop I had already re-arranged all the equipment then after that I acquired some different equipment and needed to re-arrange again. The result is inconvenient and sometimes unusable outlet locations. My recommendation to anyone planning a shop is to save electrical money by just providing some junction boxes in the attic then add conduit drops as needed. If you move the machine that was using a conduit drop, you can remove the wire and there's just a little 3/4" diam. hole to patch in the ceiling.

I did recently add a sub panel to my shop which is really nice to have especially for all the new 220 outlets I have added.

I also enjoy that my garage ceiling is over 9 feet. I can easily maneuver 8 ft. sheet goods without fear of scraping the ceiling or whacking a light.

Speaking of lights, I have 12 ceiling lights rated for up to 100W each which now have equal lumen CFL's. Additionally I have a swing-arm lamp at my miter station and another at my lathe. It is adequate lighting for most tasks but at certain times seems almost dark. My plan is to add 12 more fluorescent tube fixtures on a new switch and a few more swing arms that I can clamp to my bench or other machine stand.

Lastly I thought I had a good plan for mobility but that hasn't panned out. In the future I would like to be able to move EVERYTHING. Since some of my projects are small and some large it pays to have the versatility to move the things that are unnecessary out of the way. Not every job requires a full mitersaw station... so it should be able to pack up and get out of the way. The table saw is a bit more difficult to move. I have a Delta mobile base on my 52" Unisaw but it's a pathetic device and not really worth the effort... at least I can remove the fence and convert it to a workbench.

I think that covers my biggest issue and hopefully helps someone out there who's still in the planning stages to plan better for versatility. I guess you should expect that from a remodeler's workshop.

DC

So even with all of that advance planning for light -- extra windows, glazed doors, etc. you still find yourself thinking about doubling the amount of fixtures and swing-arms? Sounds like continuous clerestory windows and a couple of skylights should be at the top of any remodeler's shop list.

I hear you on the electrical layout. That buried conduit seems like a fossil waiting to happen, though I could be wrong about that. I like the idea of adding extra junction boxes in the attic and running conduit as needed.

Thanks for the tips,

Dan

I actually have a very similar shop to this one. I think your eyes are bigger than your stomach with that out-feed table/assembly bench. Being able to maneuver sheet goods and long boards around is as important as worktop space in a small shop and you don't have it. The table saw is also set-up such that sheet goods will need to be broken down as you bring them into the carriage doors, probably via a track saw on the outfeed table, which can be a pain. You've also neglected all the wonderful tool storage space available on the back face of the carriage doors for hand tools and clamps (where is the clamp storage?) And don't neglect that a small well insulated and sealed shop NEEDS a dust collector more than a big shop. And I mean a real dust collector with HEP collection. The other ones just create a fine cloud in the entire shop that is heath-wise hazardous can be safety-wise flammable/explosive.

I agree, Sundowner. To be fair, this is a seat-of-the-pants sketch that Justin made to get the ball rolling.

Whenever I used to set up a remodeling shop, I designed for ease of loading in and out each day, as well as big carpentry projects -- cabinetmaking in particular.

In general, I would place the tablesaw close to the door, so that I could feed full sheets from my tailgate to the tablesaw (3/4 in. MDF and Melamine are heavy and I am getting older).

Next to the outfeed table, I would try to get the sliding compound miter saw so that I could cut plywood rips to size. Farther back, I'd try to set up some sort of assembly table.

This provided a lot of work surfaces (outfeed table and assembly table) for various tasks. Under the outfeed table, I would stash power tools that I'd need frequently (skill saw, cordless nail gun), or heavy stuff that would be difficult to get to in a confined area.

In a perfect world, the tablesaw and miter saw surfaces would be the same height.

Ladders, cords and hoses were hung somewhere close to the front door.

I kept 'kits' for various types of work -- framing, concrete, drywall, painting, etc. The kits would be stored under benches or assembly tables on on shelf units, depending on how big the shop was (usually not very big).

Lighting was always insufficient, power was always insufficient, and dust collection was always insufficient. But I don't think that a remodeling shop needs a big dust collection system. I think a shop-vac based system would be fine (and actually cleaning up every so often would have helped).

Great idea about using the backs of those doors for storage -- maybe for clamps as you suggest, or maybe a small shelf that can hold fasteners. But I suspect we'll want to limit the amount of weight we load on to them.

I like the rolling clamp cart that Fine Woodworking has in their shop, I reckon we'll mimic that.

Thanks for the input,

Dan

Interesting project. I am interested in design/materials used to build the doors and how beefy you went in framing the garage door opening to support the weight of the doors. Can't find any entries to the blog related to this project that address either. Do they exist and I'm just missing them?

After a huge tree limb damaged my garage/shop (snapped the doubled 2x12 door header in half), the insurance company paid for a total rebuild. YeeHaa!

I had been planning to make some major modifications to my shop for years, so had been reading FHB, shop books, blogs, anything to get ideas on what (not) to do.

I agree with Dreamcatcher; windows take up a lot of wall space. But I'm really glad I have lots of window area & good quality windows. I truly appreciate natural light. I got them 75% off at Lowe's because I wasn't in a hurry & had flexibilty with sizing.

I bought three skylights from Craigslist and installed them on the south-facing roof- wish I had three more. Again- really love the natural light. However, feel somewhat guilty punching three holes in my well-insulated roof. Plus, ventilating the rafter bays becomes tricky. Still worth it.

Dan- I like your idea of clerestory windows. I was going to add some on the south elevation, but nixed the idea at the last minute. Wish I hadn't.

My dust collection may be overkill for your shop, but I wanted a really clean shop, so I spent a lot of time considering the layout & system. I built a small bump-out on the side of my shop to accomodate the dust collecter and ran 6" PVC underfloor (actually, underslab) to the tablesaw/jointer and to the miter saw station along w/ two smaller 4" ports above the floor for disk sander, etc. With the DC mounted outside of the shop, it's much quieter & filtration is not an issue so the shop stays much cleaner. I really like the underfloor DC piping; out of the way practically & aesthetically.

Couple of ideas:

- If you route your DC ducting underfloor, be absolutely sure of your

tool locations.

- Use self-cleaning blast gates. I believe I got mine from Veritas and they're awesome.

- Just got the IVAC system from Rockler. Automatically turns your DC on/off when you turn your tools on/off. Highly recommended.

- Add an extra port or two with blast gates around the shop.

Heating: I used to heat my shop w/ a kerosene heater & was always cold, so I was going to install a huge gas heater, but didn't like the noise. I opted for a small (10K BTU), direct-vent heater with an 8' electric baseboard and 4K watt wall-mount heater as backup. I airsealed & insulated well, so the small gas heater works fine most days, just takes awhile to come up to temperature. On really cold days, I fire everything up in the morning for an hour or two & then turn off the electric heat- works great.

Lighting: Now that I'm 50, I need all the light I can get. I asked my electrician for advice & he said he could make my shop "an operatory" with hi-bay fluorescents. He was right; I could do surgery with all that light. I have three, four-bulb fixtures mounted on the 12'6" ceiling and I have very uniform, very bright light. Highly recommended.

Speaking of ceiling height, My plates are at 9' and I have 4' of flat ceiling at 12'-6". I used a structural ridge to avoid clg. joists. I love the openness and height, but probably could have dropped the ridge by a foot or so to allow more clg. insulation & bring the trapped clg. heat closer.

Misc:

I ran speaker wire before I boarded the walls & use my ipod connected to my old home receiver and old car speakers (in a custom-built enclosure). The sound is great for a shop. I would probably move the receiver if I could, so maybe run a couple pair of wires if you're not sure of final location.

I have one wall dedicated to my miter saw w/ infeed & outfeed tables. I didn't use a vertical fence because I wanted to be able to use the fairly deep table for other purposes so I dadoed a slot for a long t-track & tape measure. A flip stop rides in the flush track & can be removed to make the table completely unobstructed.

I have two ceiling fans on a wall-mounted speed control. With the windows and doors open and fan on high, it's quite comfortable in the summer.

I was going to install a garage door opener for my 16' standard garage door, but didn't want the track ruining my headroom. I'm glad I didn't, because I rarely open the door and It's easy enough to do manually anyway.

My back thanks me for my 3/4" cdx floor. Sanded and painted, it's also easy to clean.

Good luck. Have fun!

Chris

Sportbuilder -- stay tuned for more on the door construction. We have a video coming up in a couple of weeks and a feature article in the next issue of the magazine (look for it in your mailbox in about a month).

Chris -- thanks for the looooooooong post. Lot's of great tips. We are getting ready to build the cabinets that the miter saw will sit on, and will consider leaving the fence off, for the reasons you cite. Also, I suspect that speakers will be wireless, so speaker wire will not be something that we will miss much.

With all your tips on dust collection, I am beginning to wish we hadn't so quickly dismissed it. But heck, maybe it will make a good article next year -- retrofitting a dust collection system under a slab!

Thanks for the comments and tips,

Stay tuned.

Dan

I just watched the videos on airtight drywall and I'm left with two questions.

All well and good to caulk every stud but what has happened to the need for vapor barrier? Am I that far out of touch?

Since this Is a shop why would you not line the walls with 1/2" plywood before the drywall so that cupboards, shelves, hooks, etc could be fastened any where they are needed/wanted. Now you are restricted to searching for studs every time you want to hang something - poor planning to my mind.