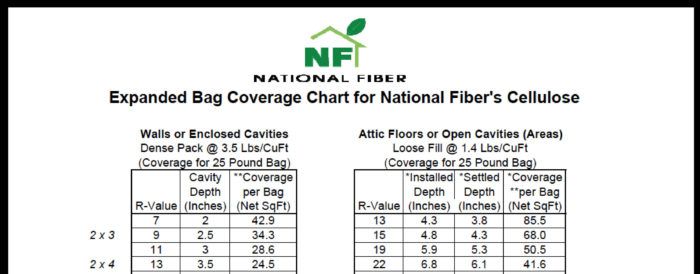

Dense-Pack Cellulose Coverage Chart

Find the expected yield for any framing cavity you’re likely to encounter.

In order for cellulose to be self-supporting, it has to be installed at a 3-1/2-lb.- to 4-lb.-per-cu.-ft. density. You can double check to see if your work or your installer’s work is sufficiently dense with this downloadable table* (click View PDF below) that shows the expected yield for any framing cavity you’re likely to encounter. The chart shows the R-value and expected coverage for a single 20-lb. bag of cellulose in framing cavities from 2 in. to 18 in. deep. At the end of the day’s work, you should count up the number of bags blown and then divide that number by the total square footage of walls, ceilings and floor space insulated (the actual square footage of the insulated space, not the square footage of the rooms on the floor plan), and that number should equal the coverage per bag as shown in the chart. If the number is higher, you’ll need more bags to reach the right density.

See Jon Riley’s full article about correct dense-packing, “Dense Pack Done Right,” in FHB #272.

* Note that this guide was produced by National Fiber before they were acquired by another insulation company.

Fine Homebuilding Recommended Products

Fine Homebuilding receives a commission for items purchased through links on this site, including Amazon Associates and other affiliate advertising programs.

Insulation Knife

Disposable Suit

Pretty Good House