What is Building Science?

Few people understand it. Nobody agrees what it is, how to learn about it, or who's responsible for it. It has never been more important

When builders began to insulate houses in the 1920s and 1930s, the exterior paint began to peel. Many painters concluded that insulation draws moisture and refused to paint a house if it was insulated. By 1938, the problem was common enough that Architectural Record published an article titled “Preventing Condensation in Insulated Structures.” The author, an architect named Tyler Stewart Rogers, argued that insulation was not the problem; indoor humidity was. He proposed a two-part solution: vapor barriers and attic ventilation.

Unfortunately, Rogers jumped to prescriptive solutions without fully understanding the problem, says Bill Rose, research architect at the University of Illinois and one of our country’s most respected building scientists. Rogers didn’t account for the effects of temperature on wood siding, and he didn’t address rain leaking in, which Rose says is “the greatest source of water in building envelopes.”

Vapor barriers and attic ventilation did not stop exterior paint from peeling, much to the delight of generations of asbestos-, aluminum-, and vinyl-siding salesmen. Nonetheless, within five years of Rogers’s article being published, his recommendations had been written into our earliest building codes, and the fledgling discipline of residential building science was off to its rocky start.

Seventy years later, our houses are bigger, more complicated, more airtight, insulated to higher levels, and dependent on ever-pricier fossil-fuel energy. Hence, the stakes of building science—comfort, health, durability, and energy bills—are higher than ever. Despite that, most architects, builders, and code officials still don’t understand moisture movement through houses. To make matters worse, there’s no easy way for them to learn about it.

Building science followed advances in comfort

Our efforts to make homes more comfortable—indoor plumbing, thermal insulation, central heating—and the problems resulting from those efforts gave rise to the first generation of building scientists, though they mostly called themselves engineers. After World War II, man-made building materials such as plywood and dual-pane windows tightened up our houses, making them less drafty and more comfortable. But the air leaks that existed in houses were not all bad.

For one thing, warm air leaking into walls and roofs helped to dry any moisture that was already there, whether from water pipes, humidity, or bad flashing. Perhaps more important, those random air leaks also were ventilating our houses. Fresh air entered houses through leaks (infiltration) around foundations and floors, while stale air exited through holes (exfiltration) in walls and roofs. Despite those changes, our houses continued to perform reasonably well through the 1960s. We didn’t have major problems with rot or mold. And then in the 1970s, the energy crisis hit.

Building science moves to the forefront

When the cost of heating our homes skyrocketed, so did our motivation to heat them more efficiently. We began to experiment—passive solar, active solar, superinsulation, double walls, Larson trusses, envelope houses—which meant that we had to ask what works, what doesn’t, and why. As a result, scientists became interested in houses. In 1977, an engineer at Princeton University named Gautam Dutt was crawling through attics to figure out why real houses were losing three to seven times more heat than his models predicted.

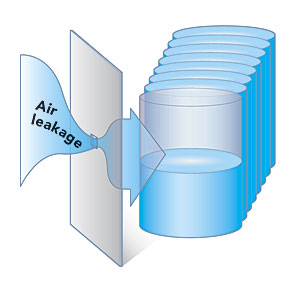

According to Martin Holladay of Green Building Advisor, his eureka moment occurred when he pulled back some insulation and found a huge air leak through an unsealed utility chase. Dutt is credited with discovering the thermal bypass, which led to the realization that hidden air leaks were a far more serious problem than the obvious ones around windows and doors that had been the focus until then. From that point on, sealing hidden air leaks became a priority in the quest for energy efficiency and lower utility bills. Within a few years, the first blower doors were being sold commercially and used to find air leaks and to test homes for airtightness.

It didn’t happen, though. In the mid-1980s, oil prices dropped, interest in energy efficiency waned, research funding was cut, and residential building science lost critical momentum, at least in the United States. In Canada and many European countries, including Germany and Sweden, interest in building science (Europeans call it building physics) continued unabated, spurred on largely by government funding.

In 1983, for instance, the U.S. home-building industry was 20 times bigger than Sweden’s, but the Swedish Council for Building Research spent more than three times more on building research than the U.S. Department of Housing and Urban Development. That same year, the National Research Council Canada published Canada’s first textbook on building science, Building Science for a Cold Climate, by Neil B. Hutcheon and Gustav O.P. Handegord. Nearly 30 years later, an American equivalent still hasn’t been published.

Mold, asthma, and construction defects on the rise

Today, we are on the threshold of another major push for increased airtightness and more insulation in houses. Whether it’s the 2012 International Energy Conservation Code (IECC), Energy Star 3.0, Passive House certification, net-zero houses, or simply the movement to improve the efficiency of existing homes, the result is the same— tighter homes—and it has some experts worried.

Rose Grant is a research architect in the Building Technology Research Unit for State Farm Insurance and a former colleague of Bill Rose’s at the University of Illinois. “I think we are on the cusp of some serious building-science issues,” Grant says, “and mold is the canary in the coal mine.” In 2001, mold claims on homeowners’ policies cost insurance companies $1.3 billion, five times more than in the previous year. In 2002, they more than doubled again, exceeding $3 billion. It’s hard to say what happened after 2002 because most insurance companies began excluding mold from coverage.

In the past, experts argued about whether mold posed a serious health threat, but according to a 2007 study funded by the EPA, “Of the 21.8 million people reported to have asthma in the U.S., approximately 4.6 million cases are estimated to be attributable to dampness and mold exposure in the home.” The same study goes on to say, “The national annual cost of asthma that is attributable to dampness and mold exposure in the home is estimated to be $3.5 billion.” Those are just health costs; they don’t include mold remediation. The authors also estimate that dampness or mold is present in 47% of homes.

Dampness and mold could be signs of a maintenance problem. But a Feb. 10, 2011, article from Bloomberg BusinessWeek reports a doubling of construction defects per housing unit from 2000 through 2005 compared with the previous six years. The article references a 2007 University of Florida study in which 69% of the 17,000 defect claims reviewed were found to be associated with moisture penetration.

You could argue that bad flashing or failure to overlap building paper correctly results from poor workmanship, not a failure to understand building science, but the distinction may not matter. As we move toward higher-performance houses, not only do we have to get the weather-resistive barrier right, but we also have to bring a high level of craftsmanship to it. To do that, everybody involved in construction—frame carpenters, plumbers, electricians, HVAC installers, insulators, roofers, siding crews—needs an understanding of basic building science that just doesn’t exist on most job sites today.

The cost of ignorance

To stay comfortable and to reduce energy costs, we’re adding more and more insulation to our homes and sealing air leaks with a vengeance. Without a thorough understanding of building science, though, you easily can trap moisture in walls and roofs, which can lead to peeling paint, mold, rot, and asthma. Ignore air leaks and you’ll pay a stiff energy penalty year after year.

|

|

Building science is not well defined

Houses aren’t so simple anymore. Nowhere is the complexity of modern construction more evident than in today’s energy-modeling software. BEopt, pictured here, is one of the simplest to use. Others, like the Passive House Planning Package (PHPP), require intensive training. All programs ask for various inputs, including the details for every inch of siding, roofing, sheathing, framing, windows, thermal breaks, climate, and so on. Sophisticated programs will then predict how any change—say, an extra inch of rigid foam—will affect energy usage or how such a change can lead to condensation in the walls.

Building science is still an immature discipline, and its scope is not well defined. The narrowest definition focuses on heat, air, and moisture transfer in the building enclosure because that’s where most of the problems are. The broader definition also includes lighting and daylighting, acoustics, fire prevention, and structure.

Viewing the house as a system

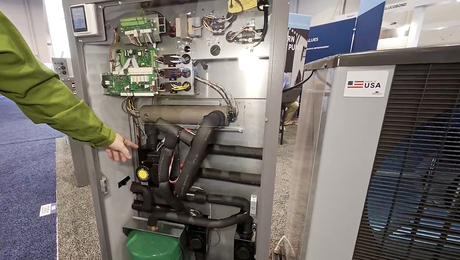

Regardless of the definition, one of the most important things that building science brings to residential construction is an emphasis on the house as a system. As houses have become increasingly complicated over the years, so too has the network of specialty trades among which we divvy up construction responsibilities. This division of labor makes it difficult for any one person to monitor how everything works (or doesn’t work) together. For example, an electrician installs the bathroom vent fan, a carpenter cuts in the dryer vent, a kitchen specialist hangs the range hood, an HVAC contractor puts in the furnace, a plumber installs the gas water heater, and a mason builds the chimney.

Who’s in charge of the home’s ventilation? Good building science not only requires that all the parts and pieces of a house work together, but it also demands that they be figured out ahead of time. The person doing the figuring matters less. It can be the architect, the builder, an energy specialist, or even a bona-fide building scientist, assuming you can find one. Although the terms building science and building scientist are not well defined, they are certainly well used.

Building Science Corp.

Joseph Lstiburek, a founder of Building Science Corp. (BSC), an architecture and consulting firm near Boston, is perhaps the person in this country most qualified to call himself a building scientist, but he’s so frustrated by all the people misusing the term that he now refers to himself as an engineer. If you’ve never heard of it, Building Science Corporation is a building science consulting and full-service architecture firm near Boston.

On the firm’s website, BuildingScience.com, you can find many free resources for designing and constructing durable, sustainable, and economical buildings—the core concerns of building science. BSC also facilitates in-person courses, workshops, and seminars that cover a wide range of building science topics for people at all skill and experience levels. Interestingly, a portion of that educational outreach is funded by the U.S. Department of Energy through its Building America Program.

Thanks to this initiative, Building Science Corporation joins NorthernSTAR, the Rocky Mountain Institute, the University of Central Florida, and several other respected organizations in the project of reducing energy consumption and moving toward a more sustainable future. The participating teams were selected from a pool of candidates in a competitive application process. The teams are particularly incentivized to develop smarter indoor air quality solutions, methods that make homes less susceptible to moisture and condensation, and systems that reduce a building’s thermal load (demand for heat energy).

For John Straube, a partner of Lstiburek’s at BSC, the dividing line between a person with a basic understanding of building and an actual building scientist is the ability to predict performance before it happens and to explain performance quantitatively afterward. “I would ask that a building scientist be able to calculate or predict things—R-values, heat loss, dew point,” Straube says.

A difficult career path

Unfortunately, it’s not easy to become a building scientist. Auburn, Penn State, and the University of Minnesota, among others, all have programs in building science. MIT, USC, and UC Berkeley offer master’s degrees in building science. But, says Lstiburek in his typically candid way, “That’s total crap. They have no connection to real building science.” Eric Burnett, who taught building science for 20 years in Canada, was frustrated during the 10 years he spent trying to establish the program at Penn State.

“One of the problems is the failure of current architectural and civil-engineering faculty to embrace the teaching of building science,” Burnett says. “They have other priorities.” There are people working on the problem, however. The National Institute of Building Sciences has a committee devoted to enhancing education across the United States in building science and technology. Paul Totten, a practicing engineer in Washington D.C., is chairman of that committee. He says, “We’re way behind Canada and almost every European country.”

One of the committee’s goals over the next five to ten years is to have “full-scale building-science master’s and Ph.D. programs with some consistency in what’s being taught. Right now, heat, air, and moisture transfer aren’t emphasized enough.” But even a degree is just the beginning. Straube says, “There’s no way to prove that windows leak based on physics. The way we know windows leak is by experience. It’s dangerous when people learn the physics and don’t have the experience.” If we’re expecting hordes of young building scientists to come pouring out of universities and help us to fix all our houses, we’re going to have to wait awhile.

Architects should be trained in building science

Because the goal of building science is to predict how a house will perform, it makes sense that architects and designers should understand it, but building science isn’t emphasized in most architecture schools. Katrin Klingenberg, a German architect now living in Illinois and the head of the Passive House Institute US, says that when she looked into the level of science training for architects in this country, “I was flat-out shocked.”

In Germany, she says, architecture students had to take six courses of building science over two years, with exams. If you didn’t pass the exams in three tries, “you had to go and find yourself a different job.” Many U.S. architects today are becoming certified Passive House consultants because the nine-day training program includes so much building science. “We’re basically re-educating a whole generation of architects,” Klingenberg says.

In fact, Carnegie Mellon University and the University of Oregon are looking to partner with the Passive House Institute US and incorporate parts of its certification program into their curricula. Rachel Wagner is one architect who has taken the Passive House consultant training. She describes the teaching of building science in architecture schools as “woefully inadequate.” Wagner thinks that part of the solution is to make building science a section of the Architect Registration Examination.

“Unless getting your license, your accreditation, depends on it, it’s not going to stick. It’s not going to be taken seriously,” Wagner says. Despite the fact that architects are involved in few residential projects (maybe 5%), Lstiburek thinks the key to improving knowledge of building science is to fix architectural education. “Architects divorced themselves from the technology of construction,” he says. “If they were doing their jobs, I’d be out of business.” He believes that if you start with the architects, the rest of the industry will follow.

Is builder licensing the answer?

Producing more building scientists and educating architects in building science, however important, will not change the way houses are built. To do that, builders need to be educated. Pat Huelman, director of the Cold Climate Housing Program at the University of Minnesota, says, “We could have the best design, the best specs, we could have the right mousetrap, but if the person building it doesn’t understand what it’s supposed to do, it may not work when you’re done.” Paul Totten agrees. “The folks actually building the buildings need to be very deep in this subject,” he says. “Just making some minor errors in the field may cost you all of the performance that you should have gotten out of the building.”

At least some people in Oregon think the answer is builder licensing with a continuing-education requirement that includes building science. Legislation to that effect passed in 2009 and began to phase in last fall. When asked what prompted the legislation, Jon Chandler, CEO of the Oregon Home Builders Association, says that during the legislative session in 2007, “builders got pummeled in the press over construction defects—mold claims, water-intrusion claims, and so on. There was a solid week of front-page, above-the-fold articles. That was the tipping point.”

Not everyone agrees that contractor licensing and continuing education are the answer. Back in the 1990s, Minnesota had a requirement similar to Oregon’s, and Huelman was one of the people who taught the building-science courses. “I started to lose a little faith,” Huelman says, “because the owner of the company, or some delegate, was going to the class and learning about building science or energy, but that wasn’t traveling down to the guy who was putting in the window or to the siding contractor who was messing up the housewrap.”

Mark LaLiberte, who helped to set up the training programs in both states, hesitates to recommend any solution that will burden builders with more regulation, but he does advocate continuing education, especially to address building-science issues. “It’s the only solution that will bring builders to the point where they say, ‘I’m going to do this because it’s my reputation, it’s my business, and I’m a professional.’” He wants builders to seek that education on their own.

One thing everybody agrees on is that building science, just like the devil, is in the details. That’s why Straube says, “If I had to pick anybody to give training to, it would always be the site supervisor first.” Here and there, in fits and starts, some builders are getting trained, at conferences and online, through green-building certification programs, through Energy Star and Building America, but no single program is comprehensive or sufficient. The quality of the education offered varies considerably, and hucksters have set up shop to exploit this critical need. Even the most conscientious builders have a hard time learning what they need to know about building science.

Performance-based codes would help

“Code development isn’t predicated on good building science,” Huelman says. “It’s a political negotiation.” He explains that it often takes several years for a building failure to show itself. Then it takes several years to develop the language in the code that leads to a fix for the problem. It then takes several more years before the code is adopted, and another several years before the code officials are sufficiently trained. “You’re 10 to 15 years behind the eight ball,” Huelman says.

Given the complexity of the code-changing process, Totten worries about another risk. He points out, for example, that when you change code requirements for the airtightness of homes, you also have to change the codes for ventilation rates. “If we have a lag on one, particularly the ventilation rate, we’re going to create a whole pool of new problems.”

Perhaps the biggest issue with codes from the standpoint of building science is that they are prescriptive. They suggest that if you vent the crawlspace or if you install insulation with the correct R-value, you won’t have a moisture problem. However, success depends on how well you install the insulation and on how well you seal the air barrier, which is why Sweden, for example, has gone to performance-based energy codes. Like the Passive House standard, Sweden’s energy codes limit total energy use per square meter and specify an air-change rate. Meeting these requirements puts considerable pressure on builders to understand the science and to get the details right.

Whatever happens with our codes, our building inspectors need to understand building science thoroughly. They are the ones assessing the quality of the energy details before they’re covered up. Inspectors also have the authority to allow substitutions for code requirements, which can be dangerous without a deep understanding of building science. But it is no easier, and no more likely, for inspectors to educate themselves than it is for builders.

Let’s admit that it’s complicated

At some point in the past 30 years, without fanfare and without most of us ever acknowledging it, our houses crossed a threshold of complexity. They became dynamic systems whose construction and performance goes beyond the abilities and understanding of many of us in the industry. Most architects, builders, and code officials still can’t explain the difference between a vapor retarder and an air barrier. It’s not that we’re stupid. We know plenty of other things, but we haven’t had to know about building science. Now we do.

Creating homes that are comfortable, healthful, durable, and efficient means learning to build airtight, highly insulated houses. We can’t keep complaining that it’s too expensive. We can’t keep saying, “Houses need to breathe,” and then use that as an excuse to be careless about how we put them together. And we can’t be lazy and rely on prescriptive solutions. Those of us who build houses really need to understand the science of how they work. We have to take responsibility for educating ourselves.

Building-Science Milestones Throughout Time

1822 French scientist Joseph Fourier develops critical equations for calculating heat flow via conduction.

1894 The American Society of Heating and Ventilating Engineers is founded.

1910 The U.S. Forest Products Laboratory is established in Madison, Wis.

1938 Architectural Record publishes “Preventing Condensation in Insulated Structures” by Tyler Stewart Rogers.

1941 Libbey-Owens-Ford Glass Company registers the trade name thermopane for its dual-pane insulating glass.

1942 The Federal Housing Authority adds vapor barriers, crawlspace ventilation, and attic ventilation to its “Property Standards and Minimum Construction Requirements for Dwellings.”

1944 The Small Homes Council is created at the University of Illinois in Urbana-Champaign.

1955 Joe Lstiburek, whom The Wall Street Journal once called the “dean of North American building science,” is born.

1959 Plywood production in the United States exceeds 7 billion sq. ft.

1973 The Arab oil embargo causes prices to quadruple.

1974 The National Institute of Building Sciences is established.

1977 Gautam Dutt, an engineer at Princeton, discovers the thermal bypass while crawling through an attic; the U.S. Department of Energy is established.

1978 Sweden establishes the first building code in the world with a requirement for the airtightness of buildings.

1980 The first commercially available blower door, the Gadsco, hits the market. Here, Marc Rosenbaum operates a Minneapolis blower door (FHB #86).

1982 Canada launches the R-2000 Program to promote the construction of energy-efficient homes.

1983 Building Science for a Cold Climate by Neil B. Hutcheon and Gustav O.P. Handegord is published.

2007 An EPA study estimates that 4.6 million asthma cases are attributable to dampness and mold in the home.

2009 Oregon passes legislation requiring contractors to get 16 hours of continuing education every two years, some of which must cover building-science issues.

2011 Bloomberg Business Week reports a doubling of construction defects between 2000 and 2005.

2012 The International Code Council publishes the first U.S. model code to mandate air-infiltration testing for homes.

Published April 26, 2012.