Hot-Water Circulation Loops

Creating a hot-water circulation loop is fairly easy, but doing so in a way that doesn’t waste a lot of energy is a little trickier. Learn how to efficiently reduce your wait time for hot water.

We’re all familiar with the long wait: You turn on a hot-water faucet and have to wait a full two minutes for the hot water to arrive. Several factors have conspired to make this problem worse in recent years: Our houses are bigger, we’re installing more fixtures and appliances that use hot water, and the plumbing code is mandating larger-diameter pipes. To top it all off, new low-flow fixtures ensure that wait times are longer than ever.

If you live in a compact house and the water heater is located in the center of the basement, you may not have this problem. However, if you live in a stretched-out single-story home and the water heater is located in an attached garage, your bathroom may be 50 ft. away from the water heater—a layout that basically guarantees a long wait.

How much hot water is wasted?

James Lutz, a research associate supervisor at Lawrence Berkeley National Laboratory, concludes that due to the long-wait problem, “about 20% of total hot-water use in single-family residences seems to be wasted.” The cost of the wasted water and the energy required to heat it ranges from $33 to $193 per household per year; the lower end of the range applies to families that don’t use much hot water (especially those with a natural-gas water heater), and the upper end applies to high-use families with an electric water heater.

Solving the problem in an existing home

You can reduce your wait time for hot water in several ways. The first step is to insulate all your hot-water pipes. The second step is to reduce the diameter of the pipe from the water heater to the fixture. (If permitted by code, 3⁄8-in. tubing can be used to serve a single lavatory, while 1⁄2-in. tubing can serve a single shower. A warning, however: If you reduce the tubing size too much, the flow rate can suffer.) As Gary Klein, an energy consultant and hot-water specialist, points out, “Compared to the time it takes hot water to arrive in 3⁄8-in.-dia. pipe at a given flow rate, it takes roughly 1-1⁄2 times as long in 1⁄2-in.-dia. pipe, three times as long in 3⁄4-in.-dia. pipe, and six times as long in 1-in.-dia. pipe.”

Another possible solution is installing a second water heater closer to the distant fixtures— either a large independent water heater or a small buffer tank to handle a limited load until the water from the distant heater arrives. In the latter case, the buffer tank is usually installed in series with the existing water heater.

Finally, if you don’t relish the thought of having two water heaters, you may want to install a pump to circulate hot water from your water heater to your most distant fixture. While this solution isn’t cheap, a well-designed hot-water circulation system will save energy, save water, and make your life a little more convenient.

Different types of circulation systems

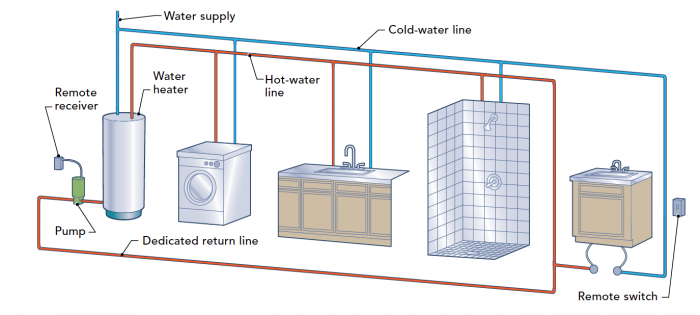

A hot-water loop uses a small pump to circulate hot water between a water heater and a distant bathroom or kitchen. Creating the loop is fairly easy; however, doing so in a way that doesn’t waste a lot of energy is a little trickier.

A continuously operating pump is clearly wasteful. The pump uses a lot of electricity, and the heat losses from the pipe add to the water heater’s load. (A variation on the continuously operating pump, a thermosyphon system that encourages hot water to flow in a circle without the help of a pump, is almost as bad.) It’s hard to predict when someone will want hot water, so putting the pump on a timer is an unsophisticated and wasteful solution, and running the pump for too many hours just wastes energy.

The only type of hot-water circulation loop worth considering is a demand-controlled system that uses a pump activated by a switch near the fixture with the longest wait time. Demand-controlled systems were developed by ACT Metlund, a company that sells the required pumps (called D’Mand pumps) and that licenses other companies (including Taco and Uponor) to sell D’Mand kits. The cost of such a kit is about $520.

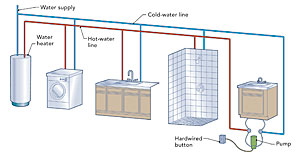

A D’Mand pump is usually installed in a vanity cabinet under a bathroom lavatory. The required switch(included with the kit) is a push-button switch that activates an electronic control that turns on the pump. In most retrofit installations, the pump uses the cold-water supply line as the return line to the water heater. The D’Mand kit includes a check valve to prevent accidental thermosyphoning, as well as a temperature sensor on the hot-water line. Once this sensor detects that hot water has arrived at the end of the loop, the electronic control turns off the pump. In most homes, the pump runs for only 20 to 45 seconds per draw. It’s also possible to control a D’Mand pump with a motion sensor; however, this approach is somewhat wasteful because the pump will turn on every time someone enters the bathroom, whether or not that person needs hot water. If the house has more than one bathroom far from the water heater, it’s possible to install separate switches in each bathroom, with each switch controlling the same pump.

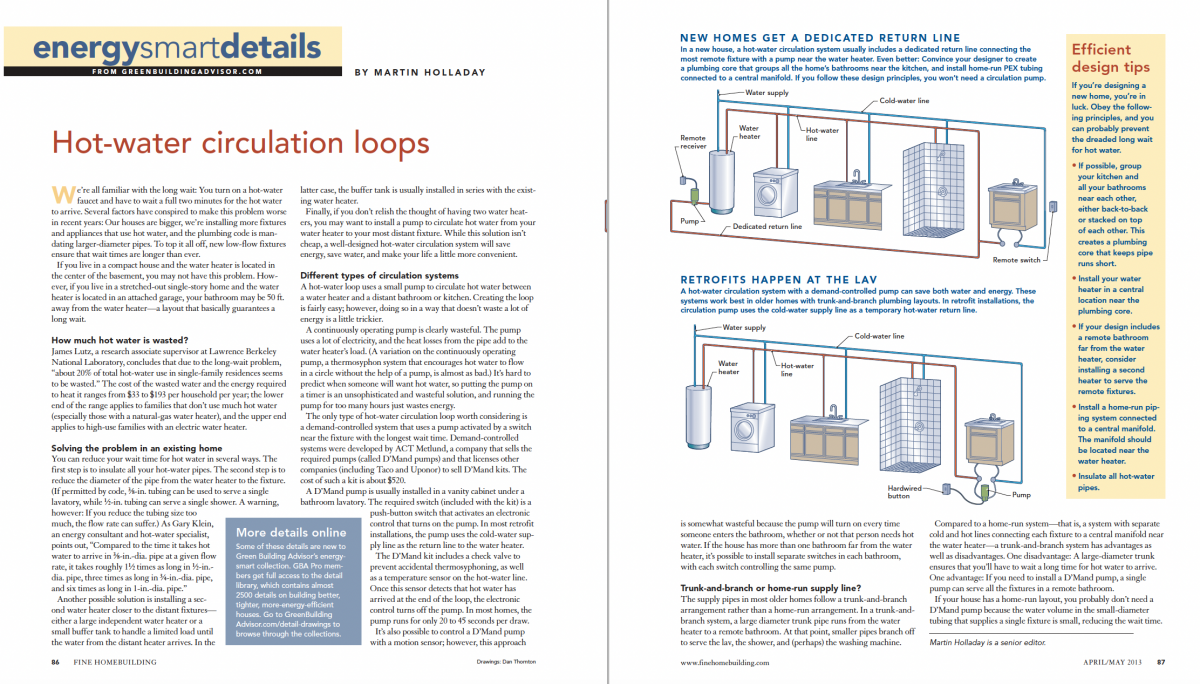

New homes get a dedicated return line

In a new house, a hot-water circulation system usually includes a dedicated return line connecting the most remote fixture with a pump near the water heater. Even better: Convince your designer to create a plumbing core that groups all the home’s bathrooms near the kitchen, and install home-run PEX tubing connected to a central manifold. If you follow these design principles, you won’t need a circulation pump.

Retrofits happen at the lav

A hot-water circulation system with a demand-controlled pump can save both water and energy. These systems work best in older homes with trunk-and-branch plumbing layouts. In retrofit installations, the circulation pump uses the cold-water supply line as a temporary hot-water return line.

Trunk-and-branch or home-run supply line?

The supply pipes in most older homes follow a trunk-and-branch arrangement rather than a home-run arrangement. In a trunk-and-branch system, a large diameter trunk pipe runs from the water heater to a remote bathroom. At that point, smaller pipes branch off to serve the lav, the shower, and (perhaps) the washing machine.

Compared to a home-run system—that is, a system with separate cold and hot lines connecting each fixture to a central manifold near the water heater—a trunk-and-branch system has advantages as well as disadvantages. One disadvantage: A large-diameter trunk ensures that you’ll have to wait a long time for hot water to arrive. One advantage: If you need to install a D’Mand pump, a single pump can serve all the fixtures in a remote bathroom.

If your house has a home-run layout, you probably don’t need a D’Mand pump because the water volume in the small-diameter tubing that supplies a single fixture is small, reducing the wait time.

Efficient design tips

If you’re designing a new home, you’re in luck. Obey the following principles, and you can probably prevent the dreaded long wait for hot water.

- If possible, group your kitchen and all your bathrooms near each other, either back-to-back or stacked on top of each other. This creates a plumbing core that keeps pipe runs short.

- Install your water heater in a central location near the plumbing core.

- If your design includes a remote bathroom far from the water heater, consider installing a second heater to serve the remote fixtures.

- Install a home-run piping system connected to a central manifold. The manifold should be located near the water heater.

- Insulate all hot-water pipes.

More details online

Some of these details are new to Green Building Advisor’s energysmart collection. GBA Pro members get full access to the detail library, which contains almost 2500 details on building better, tighter, more-energy-efficient houses. Go to GreenBuildingAdvisor.com/detail-drawings to browse through the collections.

Drawings: Dan Thornton

To view the entire article, please click the View PDF button below:

View Comments

The article states that "The D’Mand kit includes a check valve to prevent accidental thermosyphoning, as well as a temperature sensor on the hot-water line. Once this sensor detects that hot water has arrived at the end of the loop, the electronic control turns off the pump." The check valve does NOT prevent thermosyphoning, it only prevents cold water from entering into the hot water side. Thermosyphoning doesl occur with these systems. The only system that prevents thermosyphoning are ReadyTemp systems due to incorporating a solenoid valve that opens only during a pumping cycle. As for the sensor detecting when hot water has arrived is also incorrect, as it shuts off the pump once a rise in temperature has been detected.

There's an outfit (Faster Hot Water) that sells a pretty clever system: instead of a remote switch, it uses a flow sensor on the cold water input to the water heater. The flow switch will be activated any time any hot water fixture is turned on (because cold water will have to flow into the heater to replace the hot water being used). The flow switch activates a controller that turns on a high-output pump for just a few seconds to swap out the tepid water in the hot water loop with hot water from the water heater.