Windows and Doors in Double-Stud Walls

Minnesota architect Rachel Wagner shares tips for making window and door details attractive, functional, and easy to install when building a home with thick, well-insulated walls.

As noted in the previous “Energy-Smart Details,” double-stud walls have high R-values and are straightforward to frame. If you look either at the interior frame or the exterior frame of a double-stud wall, it looks like a single-stud wall. The tricky part of double-stud wall construction is the gap between the inner and outer walls that window and door openings need to bridge. This requires attention to the moisture- and air-control layers, the operation of the window or door, and the finish details.

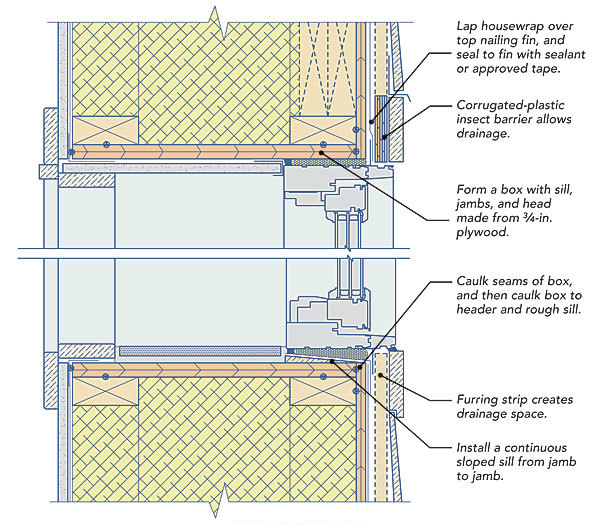

Box out the rough openings with plywood

Rough openings for windows and doors are created with a plywood or OSB box that connects the two individual stud walls. My firm makes this box from 3⁄4-in. stock, so the rough openings are 1-1⁄2 in. larger in both dimensions. The studs in both walls must be perfectly aligned at the openings to build the box.

These window and door boxes are part of the air barrier, so they must be sealed with caulk at the seams and at all framing connections. Eventually, you’ll also need to seal the gap between each box and the window or door frame. If drywall will be part of the interior air barrier, it should be sealed to the face of the box frame.

“Innie” or “outie” windows?

Placing the window toward the exterior of the rough opening creates a wide stool that can accommodate houseplants. If desired, stools can be made from a water-resistant material such as stone or tile. The interior window returns can be trimmed with drywall, wood trim, or a combination of wood and drywall.

The location of the window or door in the opening affects air-sealing, flashing, and finishing details. You can place the windows or doors to the outside of the assembly (outies) or to the inside (innies).

I prefer placing windows and doors to the outside of the opening for three reasons: It is easier to integrate flashing details with the exterior drainage plane similar to conventional wood-framed construction; many of my clients love deep window reveals; and the door-threshold detail is easier.

Headers typically go in outer wall

In most cases, the structural headers for window and door openings go in the outer framed wall only, because the outer wall usually takes all or most of the structural load. If, however, the structural load is to the inside wall or if the load is shared equally, you may need to have headers in both walls.

If the header span is very long and you want to have structural mullions between windows, plan the details carefully. A mullion doesn’t have to be the full depth of the box frame if the window or door is placed to the outside. Creating a thermal break at structural mullions is a good idea. Add a layer of rigid foam to the inside or outside of the wood mullion, or create a “sandwich mullion,” which is similar to an insulated header assembly. The joints between the mullions and the window or door frame need to be sealed to maintain a continuous air barrier.

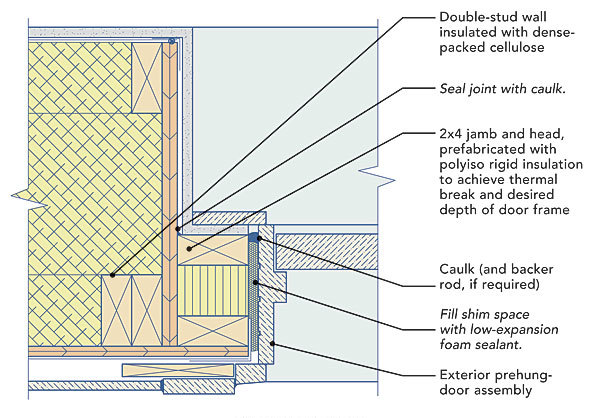

Make sure your doors can open

To make sure that thick walls don’t prevent exterior doors from opening fully, it’s a good idea to build a frame within a frame. The oversize frame is a 3⁄4-in. plywood box spanning the gap between the inner wall and the outer wall; the inner frame is sized to accommodate a pre-hung door.

Placing a door frame directly into the plywood box frame can create difficulties for door operation, especially if you are designing the opening to be wheelchair accessible. The solution is to create a single-stud framed opening within a larger double-stud framed opening. As with the structural mullion, the single-stud opening should be thermally broken and should maintain the continuity of the air barrier within the double-stud box frame.

If the frame-within-a-frame assembly for a door is near a window, or even if it isn’t, you may want to play with the trim details or the head height of the openings so that at least one layer of trim aligns. In this situation, door openings may have casing at the door frame itself and a second casing detail defining the box-frame opening. The box-frame casing for the doors then would align with the casing in the simpler window-frame opening.

Finishing touches

The deep reveals at window and door openings provide an opportunity to highlight interior finish details at these locations. Consider durability when crafting the details, especially at the windows, because the deep interior surfaces provide great places for plants, pets, and humans.

Drywall returns are inexpensive and offer a modern aesthetic. Radiused corner bead can create a softer, more durable edge at heads and jambs.

Drywall returns with a wood outside-corner detail can be a cost-effective way to enjoy the durability and beauty of wood without filling the entire opening with it. In addition, the drywall “panel” on the inside can be painted an accent color and can increase the overall brightness of the interior space.

Wood returns can be used to create a modern or traditional look. They can be solid wood, plywood with a solid edge, or even frame-and-panel construction for a rich, traditional look.

Stools can be wood or a different material more resistant to moisture; drywall stools are not recommended. Choose something simple and clean for the stool, perhaps a solid-surface material like Corian or PaperStone. Stone or tile stools add a layer of richness and provide durability. The material and detailing can provide an accent or a change in texture and color. There are many choices: granite, slate, limestone, or tile and grout. When using a thinner material like tile, it helps to use a wood edge detail.

Photos: Mark Teskey Architectural Photography. Drawings: Elden Lindamood, courtesy of Wagner Zaun Architecture.

View Comments

Thank you, Rachel, very nice clear presentation