Forming Concrete Walls

Building forms stick by stick can save on labor and materials.

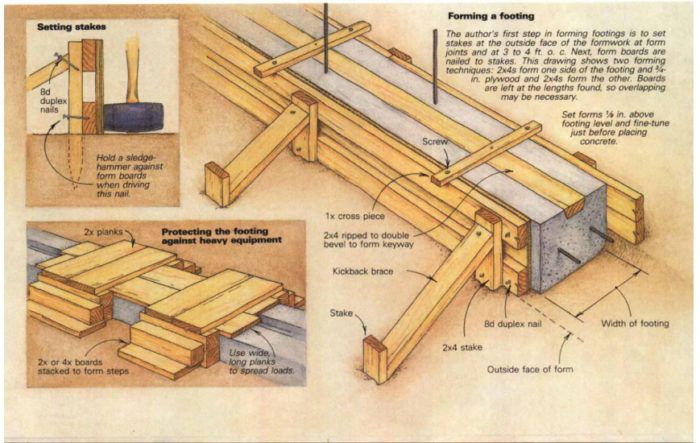

Synopsis: This article explains how the author builds concrete forms for footings and walls on site. The process is designed for a small crew and offers an alternative to a method described by a previous author on the same subject.

These days most builders choose to sub out foundation work to a specialist. The foundation contractor, with his crane, modular forms and experienced crew, can accomplish quickly and accurately what a carpentry crew would find to be a labor-intensive and basically unpleasant task. By the time you pay the labor bill, the money saved by building your own forms just might not seem worth the effort. In some cases you might even lose money. On the other hand, when the primary cost of the project is in the materials—in the case of the small builder or owner/builder, for example—building your own forms can be advantageous.If you have more time, energy and friends than cold cash, building forms is the way to go.

Reading Dan Rockhill’s article on form-building took me back to the early 70s when I worked for a company that built banks. We used wood forms for all our foundation walls. Form-building is labor intensive, so it was important for us to minimize the time spent both installing and dismantling the forms. The methods my old crew employed strike me as more efficient than Rockhill’s.

Keeping it simple

Rockhill’s article explains snap-tie wall construction. The primary difference between his approach and mine is his decision to prefabricate form panels. Nailing together a modular unit, only to tear it apart later, strikes me as inherently wasteful of both time and material. I prefer to install the forms one stick at a time with hardly any nails. This method is quick, easy and yields good results. Heavy lifting is minimized and two people can easily handle the job; in fact, I’ve written this article assuming that to be the case. (Of course, a larger crew will speed the job considerably, as various steps can be accomplished either simultaneously or by teams on the heels of each other.) Just as installation is simplified, the forms also come apart easily with minimal damage to the material. This is significant because the ease with which you can recycle your lumber is an important consideration.

Incidentally, I’d never heard the term “stem-wall” before reading Rockhill’s article. I’ve poured some 4-ft. retaining walls, usually for landscaping purposes, but when it comes to houses, I’m a big fan of full basements. That may be due partly to the fact that I grew up in tornado country, but I also regard the extra space as far too valuable to pass up. Unlike a framed addition, a basement is not something that can be easily added later. If a choice were necessary, I’d skimp on my fixtures or finish materials before I’d eliminate the basement.

For more photos and information on the steps to forming concrete walls, click the View PDF button below.

Fine Homebuilding Recommended Products

Fine Homebuilding receives a commission for items purchased through links on this site, including Amazon Associates and other affiliate advertising programs.

Original Speed Square

Anchor Bolt Marker

100-ft. Tape Measure