Mortising a hinge with a chisel

A step-by-step guide to laying out and cutting a mortise for a door hinge

If you’ve got a houseful of doors to outfit with hinges, a router and a hinge template are what you need to get the job done quickly. But these tools are expensive, and they require setup time. If you’re installing only one or two doors, you can mortise the hinges just as fast using a sharp chisel.

Unlike most cutting tools, a wood chisel is not fully sharpened at the factory. For fine carpentry work, the back of the chisel must be perfectly flat, and the beveled side must be razor sharp. Plenty of jigs are available to ease the sharpening process (for more on sharpening, see Fine Homebuilding #141, pp. 84-87), or you can send your chisels to a local sharpening service.

Becoming proficient with a chisel is useful for more than just hinges. Among other things, the mortising and carving techniques shown here can be used to install strike plates for doorknobs and dead bolts, remove broken floorboards, or make simple repairs in damaged trim.

Lay out the mortise

Step 1: Locate the back of the hinge on the door. Using a combination square—with 1⁄4 in. of blade exposed—as a gauge, lay out the back edge of the hinge with a pencil.

Step 2: Score along the ends of a hinge leaf. It’s easy to control a sharp knife cutting across the grain. Scoring offers a definite starting spot for the chisel.

Step 3: Change tools to score along the back of the hinge. Because it’s less likely to follow the grain than is a knife, use an awl to score with the grain.

Step 4: Before putting away the awl, use it to score the mortise’s depth. A couple of scrap hinge leaves—stuck together by a dab of hot glue—serve as a depth gauge.

A $10 cutting tool takes out the guesswork

With three sharp edges that match the dimensions of a typical (3-in., 3 1⁄2-in., or 4-in.) butt hinge, a Butt Marker (The Stanley Works; www.stanleyworks.com; 860-225-5111) establishes and cuts the outlines of the hinge mortise with a few good whacks from a hammer.

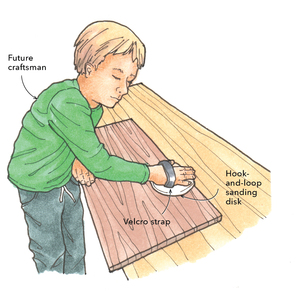

Step 5: Start with a sharp chisel. An out-of-the-box chisel such as the one on the left is acceptable only for framing and other rough jobs. The chisel on the right had been hollow-ground on a bench grinder before it was honed on a series of oilstones; flat surfaces on the outermost edges only make resharpening quick.

Step 6: A series of shallow cuts is the key to a precise mortise. Holding a 1 1⁄4-in. (or wider) chisel at about a 45-degree angle, cut across the grain in increments of about 1⁄4 in. Gently tap the chisel until the point of the blade reaches the depth score. With practice, you’ll develop a rhythm that enables you to reach the desired depth without needing to glance at the line.

A special bit makes hinge mounting a snap

After creating a flawless mortise, you don’t want a bunch of crooked screws sticking out at all angles. A #8 self-centering hinge bit, also called a Vix bit (Eagle America; 800-872-2511; www.eagle-america.com), ensures that all screws are centered and plumb. Using the hinge as a template, place the bit in the screw holes and drill.

Step 7: Horizontal slices remove the waste. Starting about 1⁄2 in. from one end of the mortise, place the blade (bevel side up) into the awl score and gently pare off the waste (photo left). You may need to start the cut with a soft hammer tap, but finish with hand pressure only. Make sure the first cut is flat and smooth, then use the finished surface as a guide for subsequent cuts (photo right).

Step 8: Shim it if it’s too low. Don’t worry if the mortise ends up too deep. One or two cardboard shims (cut from the same box that the hinges came in) easily make up the difference.

Photos by Brian Pontolilo