Q:

My brother and I have worked together building many houses. He insists that we can let the joints in the layers of a built-up center beam fall between the supporting columns. I say that the joints have to fall over the support columns. Is he tugging on my hammer handle, or are midspan joints a possibility?

Bruce Guertin, East Greenwich, RI

A:

David Grandpré, P. E., a structural engineer with C. A. Pretzer Associates Inc. in Cranston,Rhode Island, replies: In my engineering practice, I’ve visited homes to investigate mysterious wall, ceiling or flooring cracks as well as significant structural failures that at least in part could be related to the joints in a built-up center beam not falling over a support column.Usually, however, the joint itself is just one of several factors. In one case, cracks in a ceramic-tile floor were traced to a floor system with too much flexibility. The floor joists were slightly undersize, giving the floor some bounce. This problem was made worse because a splice in one of the beam layers under the floor had been placed too close to the midpoint between the supports.Together, the two problems caused the cracks.

I have also investigated structural failures in houses that had improper ventilation in a damp basement or a crawlspace. Fungal growth supported by the moisture had decayed the outer beam layers where a joint in an interior beam layer was located between supports. That decay dramatically reduced the carrying capacity of the outerbeam layers.

I have also seen unsupported joints in the layers of built-up beams without any sort of adverse results. Successful placement of joints between the support columns can be credited to either using more layers in the built-up beam than are required, performing structural calculations, considering site-specific conditions or just good luck. And luck is usually due either to high-quality wood or to a beam that has never been fully loaded.

In general, the design of wood beams is complex. Wood species, wood quality, the size and shape of the lumber, loading geometry and other variables all must be considered when you’re choosing an adequately sized yet economical beam.

When you’re sizing a built-up center beam, published tables in a lumber-span book or a building-code publication can be useful. One such publication is The U. S. Span Book for Major Lumber Species, available from the Canadian Wood Council (800-463-5091). However, the beams referenced in these tables are designed with the assumption that joints in the layers of lumber that make up the beam fall directly over supports.

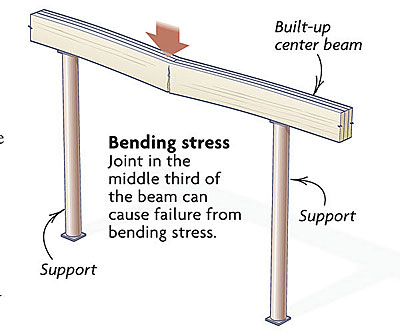

When you are designing beams, three separate forces must be considered. The first force is bending stress. A wood beam that fails due to bending stress develops a crack across the wood grain at the bottom of the beam, typically in the middle third of the span. Joints should not be located in this area.When I’m designing a built-up beam, my first step is to choose a dimensional-lumber size and number of layers based on bending stress.

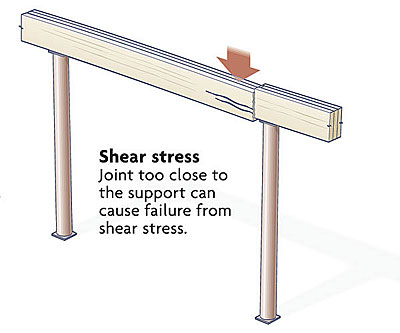

The next force to consider is shear stress. Once I’ve chosen a trial beam size, I check the member to ensure that it has sufficient capacity not to fail in shear. The most critical zone for shear is close to the supports. A beam that supports a post with heavy loads from above, located close to but not directly over the supporting column, may result in a condition where shear stresses control the design. A joint can be used close to a support only if there is enough shear capacity in the remaining layers of the beam that continue through to the support.

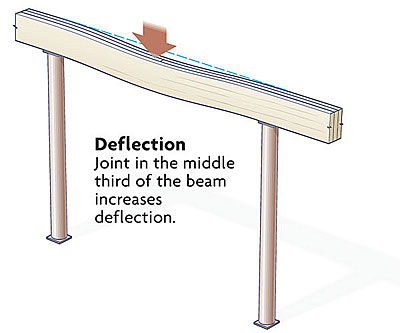

The third factor that I consider is deflection, which is the flexibility of a beam. Excessive deflection won’t cause a beam to fail (unless the allowable bending stresses are also exceeded), but it can cause cracks in floors, walls and ceilings. A bouncy floor can also be a source of annoyance for the homeowner. Maximum allowable deflections for floors are specified in building codes as a function of the length of the beam between supports. Any joint in a built-up center beam between supports will reduce the beam’s ability to resist deflection. And as with bending stresses, stiffness requirements are most critical in the middle third of the span.

If for convenience or economy a contractor locates a joint in the layers of a center beam between supports, an engineer should design that beam to locate the joint precisely. The engineer also should specify the materials for the beam and specify a nailing schedule. Most likely, the cost of engineering for this calculation will exceed the benefits. The simplest, most economical solution is locating all joints over supports.

Fine Homebuilding Recommended Products

Fine Homebuilding receives a commission for items purchased through links on this site, including Amazon Associates and other affiliate advertising programs.

Sledge Hammer

Bluetooth Earmuffs

Anchor Bolt Marker