A lot of my remodeling projects use off-the-shelf post-formed countertops. Cutting countertops to length on site with a circular saw is a challenge that requires two perfectly aligned cuts. These cuts are complicated further by the need to raise and lower the saw to negotiate the scribe strip and the front lip. Even when made with great care, the complicated pair of cuts often yields a less-than-desirable result.

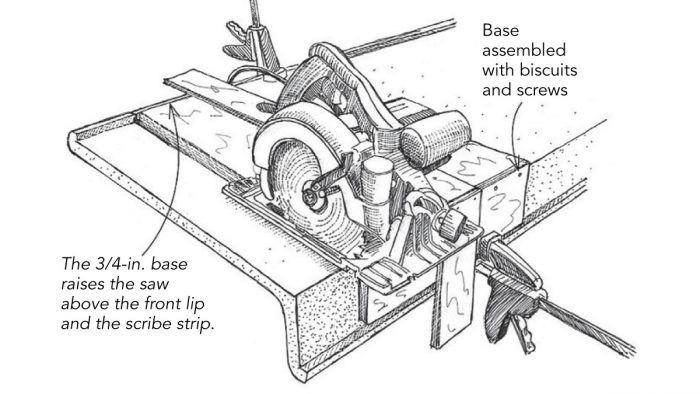

To take the suspense and the element of chance out of the process, I built the jig shown here. It’s essentially a 90° saw guide consisting of a 3/4-in. plywood base joined with biscuits and screws. The guide strip is 3/8-in. plywood.

I either screw or clamp the guide to the upside-down countertop blank, which is perched on a pair of sawhorses. The edge of the base aligns with the line of the cut I need to make. The thickness of the base compensates for the lip and scribe strip, providing a flat bearing surface while keeping both cuts aligned properly. The result is a perfect cut every time. It is almost impossible to tell where the cuts overlap. The jig not only produces a great cut, but it also improves speed and safety.

Jeff Johnson, Glen Allen, VA

Edited and Illustrated by Charles Miller

From Fine Homebuilding #240

View Comments

I'd be inclined to use a jig like this to cut 1/8" short of the desired line, then adjust the jig to use it as a router guide to remove the last bit of particle board & laminate. A router bit taking a small bite will be less likely to chip the laminate than a saw blade, which is important if you're trying to make a tight joint.