The hinge side of a door must be trimmed to width at 90°. The latch side is usually trimmed at 5° off vertical for a beveled edge. Making these long cuts straight and smooth is easy with this two-sided jig.

First, buy a fine-toothed blade for your circular saw. I prefer a carbide-tipped plywood blade. Mount it on the saw arbor, and then use a combination square to make sure that the saw’s base is 90° to the blade.

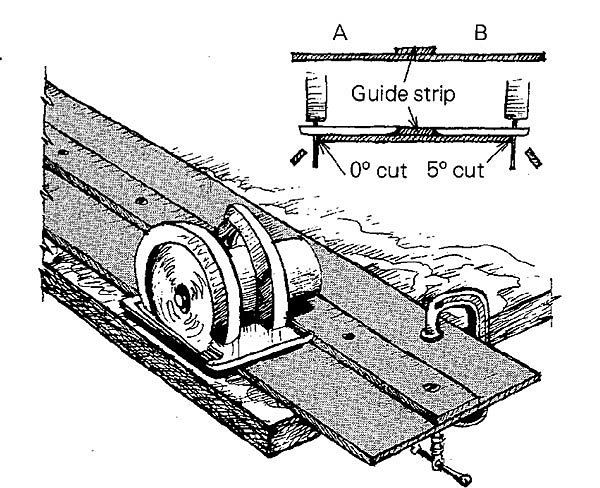

Build the jig with 1/4-in. Masonite, 8 ft. long and about 12 in. wide. Accurately place a straight Masonite guide strip, 2 in. wide, down the middle, gluing and tacking it firmly into position. Leave dimensions A and B large at first.

When the glue is dry, trim the sides with your saw — one side with the blade set at 0°, the other side with the blade set at 5°. Mark the respective sides clearly. When the jig is clamped to the work, the appropriate edge will register the line of cut. For smooth operation, apply furniture wax or car wax to the surfaces on which the saw’s baseplate slides.

For crossgrain cuts, first run a knife along the cutline to sever the surface fibers of the wood. This will eliminate splintering, which can be a problem with veneered doors.

— Philip Zimmerman; Berkeley, CA

RELATED STORIES

Got a Tip?

Do you have any great tips like this one on how to make a jig for trimming doors? Share your methods, tricks, and jigs with other readers. Tag them @FineHomebuilding on social, email them to us at [email protected], or upload them to FineHomebuilding.com/reader-tips. We’ll pay for any we publish.

View Comments

Here in New England I would not use Masonite as it is susceptible to changes in humidity. Of course, if your shop is fully air conditioned and humidity-controlled, Masonite might be fine. Rather, I would use 1/4" marine grade hardwood plywood (preferably from Europe; definitely NOT from China) as it comes in 1/4" thickness with 5 plies. While not infinitely waterproof, it would be quite stable under varying humidity conditions. I might also consider a guide strip thicker than 1/4" (or use 2 layers of 1/4").

And when replacing existing doors, first mark the existing doors for any differences you would want in the new door. Then remove hardware and place the old door hinge barrel side up on the new door and trace the borders, hinge mortises and latch hole and mortise onto the new door. On the bevelled edge, use a combination square to locate the wider part of the bevel, top and bottom. Adjust any

thing desired based on your observations and notes on the old door. Cut, drill and mortise the new door and wallah, it will fit the old door opening nicely. Nothing like having a ready-made pattern that's accurate!