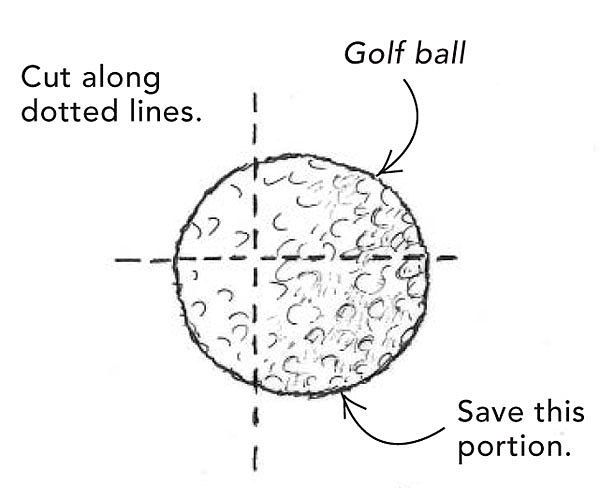

Coping crown molding with an electric jigsaw is much easier when you attach a radiused auxiliary base to the jigsaw’s standard flat base. But I was stumped about making this modification until I spotted a golf ball on my shop bench.

As shown in the drawing, I started by cutting the ball into unequal parts. I did the cutting on my bandsaw after driving a couple of 3-in. drywall screws into opposite sides of the ball to act as handles. The screws kept my fingers a safe distance from the blade. Then I made a perpendicular cut in the larger portion. Still at the bandsaw, I cut a slot to accommodate my jigsaw’s blade.

Next, I drilled a couple of 1/8-in. holes in the saw’s base, on opposite sides of the blade, for a pair of screws. I positioned the slotted golf ball as shown in the drawing and affixed it to the base with a couple of small screws.

This jig provides a pivot point right where the blade enters the back side of the molding. As a result, I have the control to make exact relief cuts. I have found that longer blades are useful for cutting big crowns. Different configurations could be obtained by cutting the ball into segments of various sizes.

Jim Delvin, Des Moines, WA

View Comments

this is hard to fathom without including the other illustration that goes with the original publication of this tip