Trimming arched windows can be a problem, especially with complex molding patterns. This method requires two pieces of molding to form one finished piece of curved, paint-grade trim.

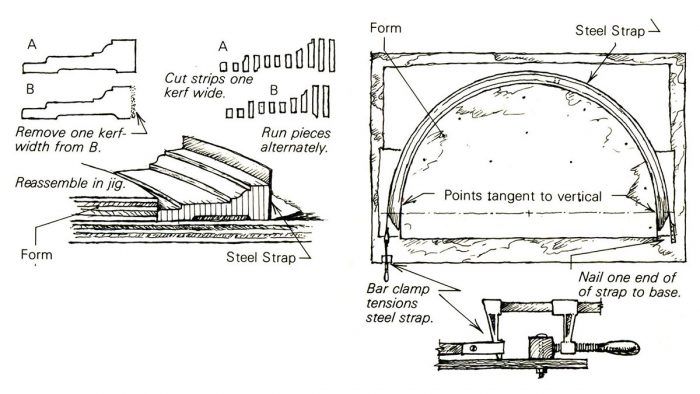

First, determine the distance between the inside edges of the vertical moldings (let’s say 4 ft.). Cut the appropriate radius out of a sheet of plywood thicker than the trim and nail it to a plywood base. Our 4-ft. diameter arch will need a 2-3/4-in. trim piece a little over 7 ft. long, cut from two 8-ft. pieces (A and B in the drawing) to allow a margin of error.

Remove material the width of the sawblade (the kerf) from the edge of piece B and then set the table-saw fence to leave a strip exactly one kerf wide with each pass. You don’t have to remove the fence again. Running the two pieces through the saw alternately makes it easier to collate the thin strips. If your molding has a hollow back, tack shims in the jig, one foot on center, to ensure proper alignment during clamping. Baste the strips with your favorite glue, place them in sequence against the curved form, and clamp the steel strap in place. I use a 26-ga. steel strap cut from an old downspout for a clamp; one end is nailed to the base, and the other has a loop large enough to anchor the end of a bar clamp. A bar clamp is better than a C-clamp for this application because the sliding jaw allows tensioning without exhausting the reach of the threaded shaft.

When the glue has set, scrape off the excess and sandpaper the rough edges. The junction with the vertical trim should be a 90° cut in the base of the arch at the point tangent to vertical.

—Jud Peake, Oakland, CA

Edited and illustrated by Charles Miller

From Fine Homebuilding #6

View Comments

Or find someone in your area who knows how to run a shaper...

Clear as mud.

Using a typical 1/8" kerf blade, that is a lot of laminations for say, 3 1/2" casing.--and probably needlessly too thin to bend around the form. Perhaps through-cuts using a dado blade set would give wider kerfs and fewer laminations.

Great suggestion.

Sounds good in theory, but getting these cuts perfectly spaced like this is pretty difficult in practice.

In 2023 they make flexible trim which are paintable and you dont have to take hours making the curved trim and can finish the job in a fraction of the time and not have to charge the customer hundreds of dollars for the time it takes