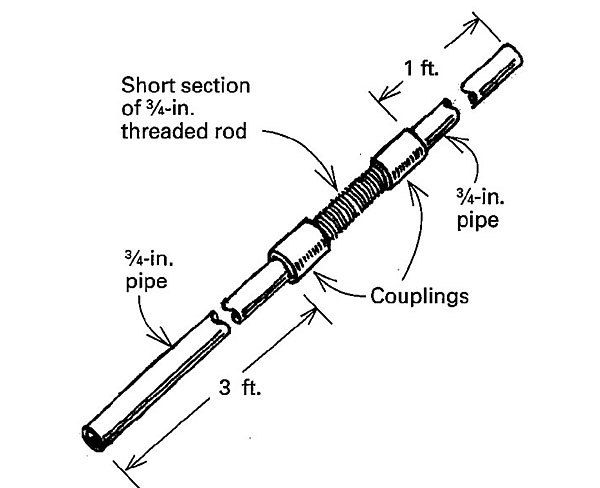

Driving a ground rod for an electrical system can be a tedious task if you don’t have the right equipment. The problem is putting the force of the mallet where you want it. The end of a ground rod is a pretty small target.

The drawing shows a homemade ground-rod driver that can help you deliver accurate force to the rod with each blow. One end of the driver is a 3-ft. length of 3/4-in. pipe. The other end is a 1-ft. length of the same material. The two ends are linked by a pair of couplings with a short length of threaded rod. Be sure the pipe and the rod are screwed into the coupling as far as possible.

Start driving by slipping the 3-ft. length of pipe over the rod. The bottom of the threaded rod striking the top of the ground rod drives it deeper, and with the end of the rod thus contained, you can deliver maximum force to the rod without worrying about the business end of the driver — the section of threaded rod — slipping off the target. If necessary, you can add weight to the rig at the threaded joint. Use the short end of the driver to finish the installation.

Don E. Schaufelberger, Phoenix, AZ