I read with interest the article Making Trim From MDF, by Jay Goldman. I, too, have been making moldings from MDF for a number of years, and I agree with Mr. Goldman’s appreciation for its workability in paint-grade situations. Although I haven’t made any curved moldings yet, I routinely reproduce one of the more common door and window casings that turn up on middle-of-the-road tract houses in my California neighborhood. Around here, it is typically called beveled, or streamlined, casing. Making it out of MDF brings the price down to about one-tenth the amount charged by my local building supply for fingerjointed material with the same profile.

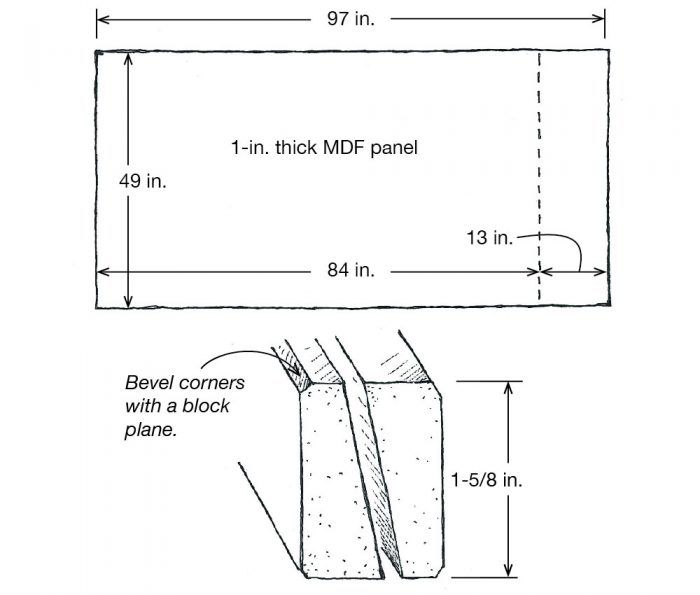

I start with a 4-ft. by 8-ft. sheet of 1-in. thick material, and make my first cut at the 7-ft. mark as shown in the drawing. This gives me a 4-ft. by 7-ft. piece and a 13-in. by 4-ft. piece. Next, I reduce the big sheet into a pile of 7-ft. long strips, 1-5/8 in. wide. The 4-ft. long piece gets ripped into strips that will make header casings.

Now I set my table saw at 7° and rip each strip down the middle. This has to be exactly down the middle so that the pieces end up the same thickness. You can use the cut side as the finish side, but I prefer to expose the factory side. That’s because MDF has a smooth, hard finish that accepts paint well. The next step is to knock down the sharp, exposed corners with a block plane.

Using these dimensions, a 1-in. thick sheet of MDF yields about 60 7-ft. pieces, and about nine 4-ft. pieces.

—Larry Hart, Reseda, CA

Edited and illustrated by Charles Miller

From Fine Homebuilding #113

View Comments

Having lived with MDF trimming for 3 years, it is the worst excuse for 'Fine' i have ever experienced. It is soft and shows every small contact.

Poor product to ever consider.

Yes, a poor, moisture absorbing substitute for any professional treatment, but it is "middle-of-the-road" dry California and those houses are slapped together at the very lowest cost. You get what you pay for.