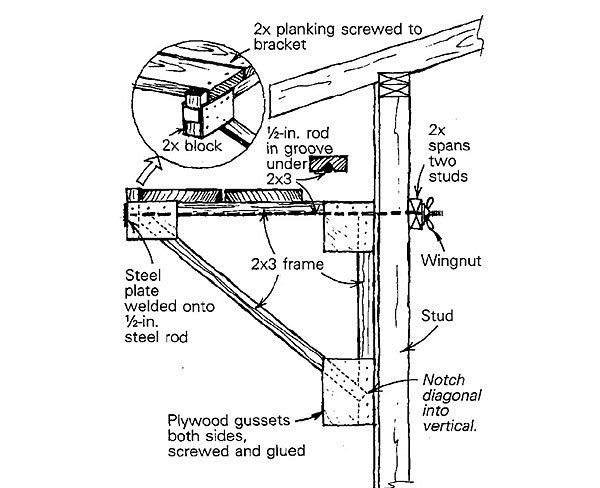

Whenever my crew and I need to work around the edge of a roof, we erect a row of planks around the roofs perimeter and support it with large brackets that bear against the walls. The brackets are triangular frames made of 2x3s (see drawing) and have plywood gussets at the comers. A length of 1/2-in. dia. steel rod is let into a groove in the bottom of the horizontal 2×3. It has a welded plate on the outboard end, and it’s threaded on the inboard end.

To use the brackets, we first drill a hole in the sheathing at the desired height on the wall, right next to a stud. The steel rod extends through the hole, and then through a scrap of framing lumber long enough to span two studs. The bracket is then secured with a big wingnut. We space the brackets approximately 10 ft. o. c.

I think the staging makes rafter and truss installation much safer and easier, and it seems to speed up eave and soffit detailing, as well as roof-edge shingling. The staging is completely independent of uneven backfill, or other ground conditions that bedevil scaffold installations.

Peter Evans, Sackville, None