Anyone who has ever renovated an old house has probably dealt with a floor system that is a bit too springy. It seems that 2×8 rough-cut joists were once used everywhere, regardless of the span.

I recently started work on a home built in the 1890s that has 2×8 joists on 16-in. centers, spanning 14 ft. They were also installed without blocking and were beginning to twist in spots. The basement has a dirt floor but plenty of headroom and usable floor space, so I didn’t want to add a midspan beam with columns. Beefing up the joists was the only answer.

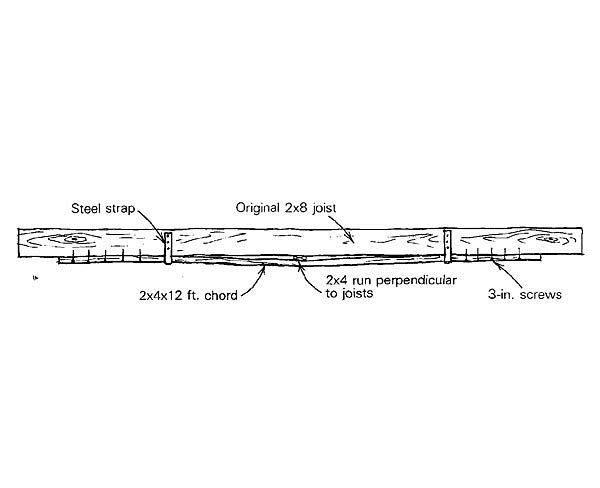

For blocking, I ran a 2×4 perpendicular to the joists across their bottoms at the center of the span. With the butt end of the 2×4 against the foundation, I worked my way across the floor, plumbing the joists and screwing through the 2×4 into each joist to secure them.

Next I turned each joist into a bowstring truss. I used drywall screws, steel straps and construction adhesive to attach 2x4x12-ft. chords to the bottom of each joist, as shown in the drawing. I used five 3-in. drywall screws per side to pull the 2x4s into place over the block in the center of each joist. Then I added a pair of steel straps to get some fasteners working in shear in addition to withdrawal. This took only a few hours to do, and the floor now feels like it has 2×12 joists.

David Wallace, Annapolis, MD

Edited and Illustrated by Charles Miller

From Fine Homebuilding #64

View Comments

I tried but could not understand what you did in the last 2 paragraphs. Did not understand bow string truss and chords. Could you please add some more pictures.

Thanks

I think that using structural wood screws would be a better option in place of drywall screws. Otherwise, great info!

Great concept and execution! Did you consider using steel cable instead of 2x4s? thanks !

Also, would 2x6" chord add any stiffness to the floor?

This is a joke right? The 2x4is is flat (the bendable side). Not sure the strap does much except save the drywall screws from snapping. Why not sister them along side the 2x8 (preferably 2x6's or 2x8's). Screw and glue one half side of each. Then force the other side up (putting both new and existing in tension) and glue & screw.

I agree with timhoover - use structural wood screws instead of drywall screws - much better ductility.

Org49 - You should search the 'net for images of bowstring trusses - the similarity will become obvious.

Depth of the joists is critical when it comes to constructing a stiff floor. Sistering 2x4s to the side will not increase the stiffness as much as the added 'depth' of the joist at midspan as David's method shows. Additional help would come from solid blocking installed between the joists at 1/3 points (i.e. 2 rows) - blocking, NOT bridging. This forces load sharing to adjacent joints which also helps to minimize the 'springiness'.

Wood screws and proper blocking a must. The thought here is that mechanically adding 1.5" of depth to the joist will strengthen it. If the 2x4 were of equal or better wood (species & grade) and were glued for the entire length of the joist with a structural adhesive similar to a glulam beam this would work to something less effective than 2x10s. This 'bow' of 1.5" reverse crown is not going to have any effect on the strength of the joist. Merely 'plumbing' the joists took most of the spring out but he didn't test the floor at this point (per the tip). And yes CT_Yankee, proper full blocking, will maintain the joists in their strongest structural plane.

Dirt floor, so digging footings was a non-issue. Inset a beam and hang the joists maintains headroom and a properly sized beam could reduce the number of posts. And the beam didn't have to be at the centerpoint. 2x8s span up to 12', offset the beam and posts to maintain the spacious room feel.

The first blinking red light over this tip is the use of drywall screws for a structural application in a basement with earthen floor on the US east coast. Then there’s the metal strapping that is, at the most, protected with a couple mils of zinc plating. Look, a basement with an earth floor is nothing more than a very deep crawl space with even greater humidity/condensation problems. The very minimum in corrosion protection for applications in a humid environment would be hot dip galvanised, whereby polymer coated deck screws would also be acceptable.

The five drywall screws might pull the 2x4 chord into place and keep it there until the steel straps are added - but long term? And that’s without factoring in the corrosion issue.

Putting this all in perspective, one could say ‘so what, all that is being done is to correct springiness.’ That is true. The floor is not collapsing now and the only implication of the solution failing is that the floor will get springy again. Thing is though, the home owner paid to have the springy floor fixed. If it’s not fixed with a procedure that provides a reasonable life expectancy, then the home owner has been cheated.

The trouble with so many of these seat-of-the pants solutions is that their originators don’t provide us with a documentation of what the solution looks like some years down the road. Everything might look straight, strong and shiny when the job is turned over to the owner, but what that owner, or the next owner, has to deal with later is another thing entirely.

About the only correct practice in this tip was to untwist the joists and hold them in place with 2x4 bridging (not blocking).

When you say "plumbing the joists" do you mean jacking them up until level on the floor surface?