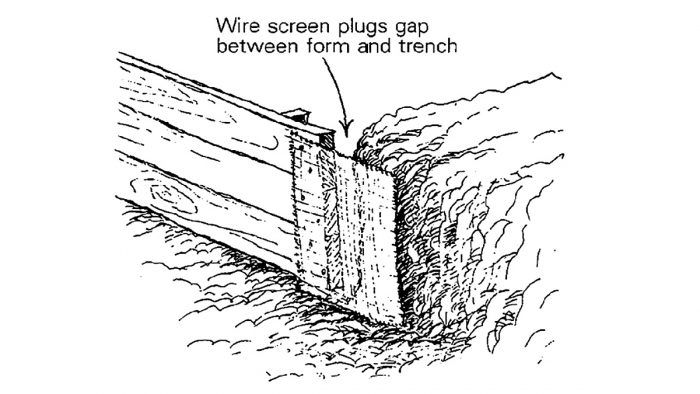

I recently poured grade beams and stemwalls for a house foundation on a hillside lot with stony soil. When the wooden form boards butted up to a trench or embankment, the irregular surface of the ground made for ragged gaps that were difficult to seal against the pressures of several feet of wet concrete.

To solve this problem I used roofing nails to tack 1/4-in. by 1/4-in. wire screen over the ends of the form boards and across each gap (see drawing). The weight of the concrete forced the screen to sit tightly against the bumpy ground, and the screen kept the concrete inside the forms. In those places where the concrete pressure was greater or the gaps wider, I simply doubled up the wire.

—Glen Carlson, San Diego, CA

Edited and Illustrated by Charles Miller

From Fine Homebuilding #63

View Comments

Great idea -simple and efficient.

Wire screen seems a strange material for sealing. I would expect that grout would leak through 1/4'' x 1/4'' screen and lead to rock pockets in the concrete. I wouldn't use this method myself nor would I allow a contractor to use it.

I stand by my comment of 2 1/2 years ago. The screen needs to be sealed, say with a plastic foil or by foaming on the reverse side.

A better solution is to use a piece of geotextile fabric. Also very good for plugging the gaps underneath the bottom form board. No future rust and very minimal grout leakage, if any.