Sanding Frames for Belt Sanders

These add-on accessories keep sanders flat to prevent ugly gouges

Belt sanders are hard to beat for removing lots of wood in a hurry, but the flip side is that they can also ruin a work piece in the proverbial blink of an eye. The introduction of variable speed controls—now a fairly common feature—help tame even the most powerful of these beasts, but several manufacturers including DeWalt, Bosch and Makita offer auxiliary sanding frames that can keep things even more manageable. The wide footprint of sanding frames lets the entire assembly glide over uneven surfaces and prevent sander tilting and gouging.

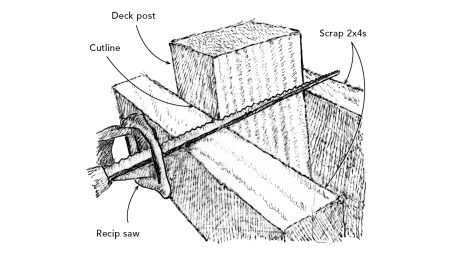

Uneven joints benefit the most from sanding frames. I mostly use my own belt sander to flatten glued-up boards for deep jamb extensions, tabletops, and such. The joint below is a little worse than usual, but a misalignment of about 1/32-in. is pretty common. Without the sanding frame, it’s pretty easy to produce a gouge as shown, which is why I hardly ever flatten boards without one.

Setup is a snap. Dropping a belt sander into a cradle like this one increases the sander’s footprint, limiting any tendency to rock or tilt; it also provides a reference surface for controlling the depth of cut. The fastening particulars vary from sander to sander, but securing the frame only takes a minute or so.

Sand against the grain until the sander finds its groove. I like to start the sander facing at about 10 or 11 o’clock and then move it back and forth slowly once the belt grabs into the surface. This is also helpful when sanding without a frame, although the belt can still find a way to dig in, especially at the rear wheel. If I need to remove lots of stock I sometimes start by sanding corner-to-corner, but I always finish up by sanding parallel to the grain.

Adjusting sanding belts to match frame depth

Belt sanders have adjustment dials that limit the depth of the belt relative to the face of the work piece. When using a sanding frame, the belt must be adjusted slightly to compensate for the additional height that the sanding frame adds to the sander. In other words, sanding frames add a slight space between the sanding belt and the work surface

But this is easily compensated for, and in the case of this DeWalt model, turning this black knob on the sanding frame raises or lowers the sander relative to the frame. Note that this adjustment happens on the frame, not the sander itself.

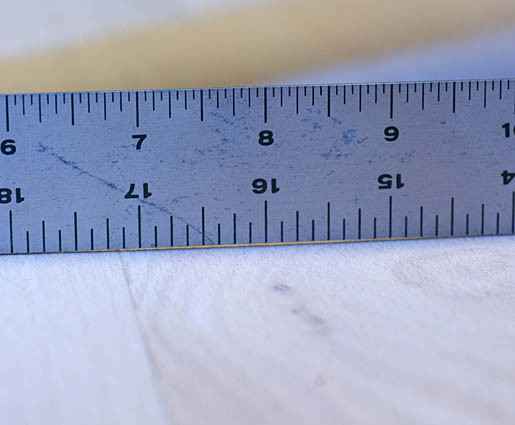

I usually start with the depth set to take off a bit less than any height difference between the glued up components, typically around 1/32-in. Here the sander is set to remove around 1/8-in., which is about as deep as it can extend.

Tale of the tape. Under exactly the same conditions (same sander, sanding belt, duration, wood type, etc.), the test using the sanding frame produced a dramatically flatter and smoother result. To get this joint totally flat, I’ll finish up with a random orbital sander and a fine-grit paper.

Confused about which belt sander to purchase? Read Michael Standish’s Belt Sanders Get Better, a review of eight 3-in. by 21-in. models from the October/November 2007 issue of Fine Homebuilding.

Photos: Jean Paul Vellotti

Fine Homebuilding Recommended Products

Fine Homebuilding receives a commission for items purchased through links on this site, including Amazon Associates and other affiliate advertising programs.

Bosch Wall Scanner (GMS 120)

Metabo HPT Impact Driver (WH18DBDL2)

DEWALT 18v Cordless Multitool (DCS355)