How To Drill Pilot Holes Without a Bit

Sometimes the right tool for the job isn't a tool at all. In this tip, watch Chuck Miller make a pilot hole by working backwards.

Predrilling without the drill

Gregg Roos, from San Francisco, California writes:

Impact drivers are so good at driving screws that the practice of pre-drilling a pilot hole seems to be on the wane. But if I can’t afford a snapped screw, or it’s critical that the screw pull tightly together two pieces, a pilot hole is important. Rather than get out another drill, I use this shortcut.

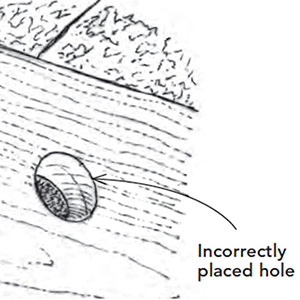

First, I drive the screw through the top piece, stopping at or near the back side. This forms a “pre-pre-drill” hole that guides and speeds step number two.

Next, I spin the screw back out, leaving about an 1/8 in. of the screw in the wood. This isn’t critical–just a little bit still in the wood to guide the screw for step three.

Now with the impact driver still in reverse, I push the screw downward, working the driver up to full RPMs, forcing the backwards-spinning screw through the workpiece. This process, which is accompanied by a small curl of smoke, only takes about 5 seconds–less time than it took to read this.

Now that I’ve effectively pre-drilled the top workpiece, I simply switch the driver to forward and drive the screw in as usual. The screw threads will now strip out in the top piece, even in hard or dried out wood, and the chance of a snap off are vastly reduced.