Just enough plus a little bit better –

Frustrated with lifting huge site built tables that seem to gather more dust than my great aunt’s figurine collection, I built this 12’ table based on the theory of a box-beam. The table weighs 46.5 lbs and is designed to fit the saw’s swing and base footprint. Experience has shown me that in most cases sawhorses are needed to store material nearby so this feature was not incorporated into the table design.

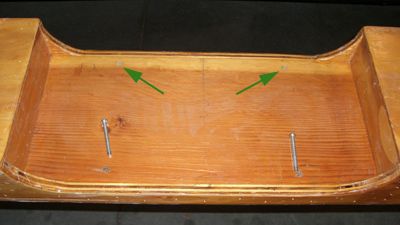

Construction: Sides ¾” plywood – top/bottom ¼ plywood – 45” inset 1 1/4 fir base, the bottom sheet is spliced directly under the base. The table has two internal braces to prevent twist and all joints are glued and stapled, the outside is finished with a spar varnish top coat. The saw base is 8/4’ from the ends and the saw can be positioned in either direction and upside down by two screws with inset “T” nuts.

The table has no noticeable deflection under normal loads but will deflect ¼” under a 208.5 lb point load with supports at each end…ok perhaps I am past 208 wearing nailbags. I don’t seem to have a problem with cutting wide boards as the table supports most of the width of the small amount of shelving that I might cut. At first glance the table weight might seem high but it does feel light for the overall length. By the success of this design I am considering thinner sidewalls along with a thinner base-inset to reduce the weight even further…of course this will have to wait until the new saw arrives.

View Comments

Well done..Keep it up..