How it Works: Wall Scanners

Associate editor Rob Yagid explains how wall scanners detect wood and metal studs, live electrical wires, and ferrous and nonferrous metals.

Synopsis: The pocket-size gadgets that can detect the location of framing behind drywall and plaster used to be called stud finders. That term, however, is now a bit misleading because better-quality tools detect much more than studs. Associate editor Rob Yagid explains how these tools, now called wall scanners by some companies, detect wood and metal studs, live electrical wires, and ferrous and nonferrous metals.

They used to be called stud finders, the pocket-size gadgets that could detect the location of framing behind drywall and plaster. That term, however, is now a bit misleading because better-quality tools detect much more than studs. Wall scanners, as some companies refer to them, can detect studs, live electrical wires, and metal pipe. Some, like the Bosch GMS 120 featured here, can even detect the difference between ferrous and nonferrous metal, and do so with remarkable accuracy. Not all wall scanners operate exactly the same, but the Bosch unit is a good example of the technology in use. For a complete review of the latest offerings in wall scanners.

The best wall scanner costs around $100. You can drop that kind of cash and just trust that the unit will work as it should. Before purchasing a wall scanner, though, it’s helpful, and certainly reassuring, to understand precisely how it works.

Wood- and metal- stud detection

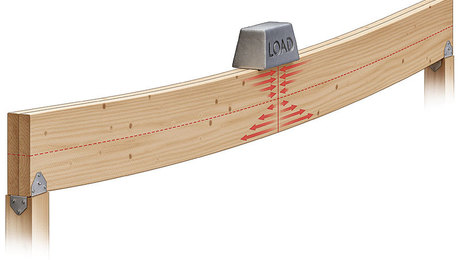

Capacitive sensors in the middle of the scanner detect the location of wood and metal framing components. The wall scanner generates an electric field that can penetrate a wall cavity up to 1-1/2 in. Materials influence this electric field differently based on their dielectric constant. Wood and metal studs have a much higher dielectric constant than the voids of air filling the stud bays and have a greater influence on the electric field. The capacitive sensors analyze this influence in the electric field to determine the presence of a stud in the wall. Simultaneously, an inductive sensor distinguishes wood members from metal components.

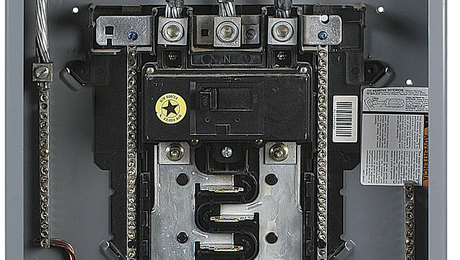

Live-wire detection

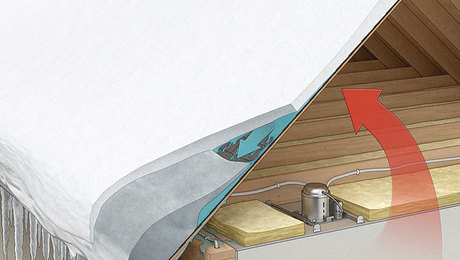

Circuitry in the top of the unit houses 50/60 Hz. sensors to detect the presence and position of live wires. The sensors act as a receiver, and if they detect a 50/60-Hz. Signal the frequency in which AC current is transmitted from power plants to residences within the wall cavity, the unit flashes and beeps. On this unit, a bar graph on the display screen helps to determine the precise location of the live wire. The number of segments displayed in the bar graph indicates the strength of the AC signal. These sensors are suitable for detecting only 110v to 230v wires, and will not detect non live wires or telephone cables. These sensors can detect live wires at a depth up to 2 in. inside a wall cavity.

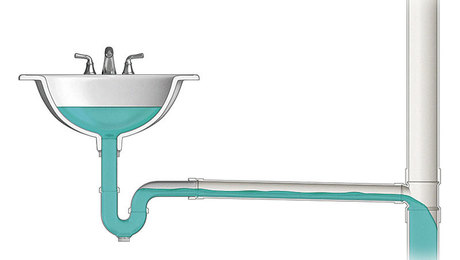

Ferrous- and nonferrous- metal distinction

An inductive sensor in the middle of the wall scanner locates and distinguishes nonferrous metal, such as copper supply lines, from ferrous metal, such as older, cast-iron waste lines. The sensor generates a magnetic field, which is boosted in the presence of a ferrous (magnetic) object, or deformed in the presence of a nonferrous (nonmagnetic) metal. The two types of metal are determined by analyzing the degree of deformation between the magnetic fields in what is called the phase shift. Nonferrous metal creates a 90° phase shift, while ferrous metal creates a 0° phase shift. An inductive sensor can detect metal up to a depth of 4-3/4 in. inside a wall cavity.

For more photos and details on how wall scanners work, click the View PDF button below.

Fine Homebuilding Recommended Products

Fine Homebuilding receives a commission for items purchased through links on this site, including Amazon Associates and other affiliate advertising programs.

Milwaukee Cordless Tablesaw (2736)

Milwaukee Compact Cordless Router (2723-20)