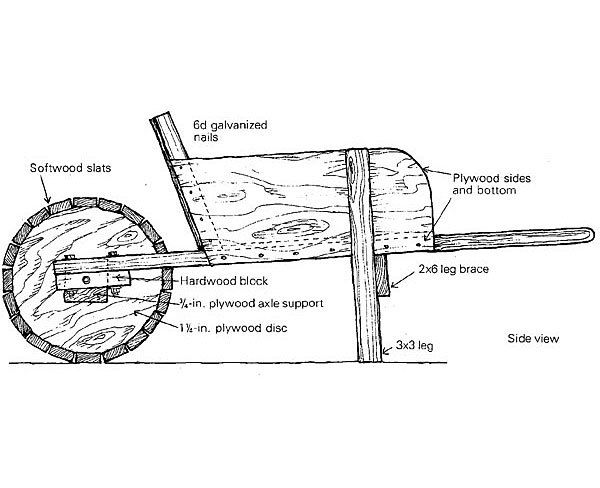

A couple of years ago I watched a neighbor struggle through the mud with a load of firewood in his wheelbarrow. The wheel was too small. Movement was all but impossible because there simply wasn’t enough surface area to keep the front end up. Not long afterward, I designed and built the wheelbarrow shown in the drawing below. Handles for the wheelbarrow were cut from a 6-ft. length of full-dimension 2×6, ripped diagonally so that the portion over the wheels (the area that usually breaks first) was about 4 in. wide. The handle area was rounded a bit with a router. The wheel was fashioned from two 20-in, discs of 1-1/4-in. plywood. These were covered with softwood slats about in. thick and 1-1/2 in. long.

The axle was formed from a section of 3/4-in. steel pipe about 22 in. long. This was inserted through the center of the wheel and fastened in place with epoxy and a couple of scraps of 3/4-in. plywood on each side. Bearings for the unit were made from hardwood blocks about 2 in. by 4 in. by 10 in. These were drilled about 1/32 in. oversize and bolted in place to take the axle. I use a few drops of 90-wt. gear oil on the axle from time to time as a lubricant.

The rest of the construction is fairly straightforward. I used a few scraps of 1/2-in. by 5/8-in. plywood for the sides and bottom, fastened with glue and 6d galvanized nails. I used 2×2 blocks in the corners for nailers. A couple of coats of Cuprinol gives protection from the weather.

The completed unit cost me less than $4 and took three hours to build. It is light, tough, holds a lot, and rolls more easily than commercial units. Its large wheel will carry tools and building materials through mud and over soft lawns without sinking in and leaving marks.

Other than low cost and simple construction, I think dependability is this wheelbarrow’s biggest virtue. It will never have a flat tire.

Mark White, Kodiak, AK