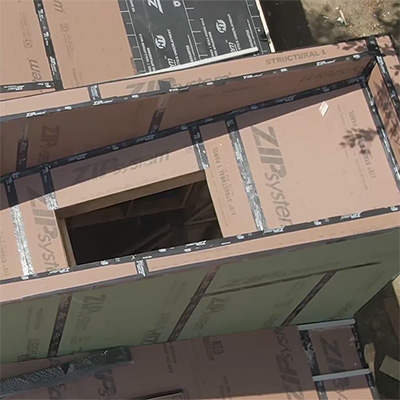

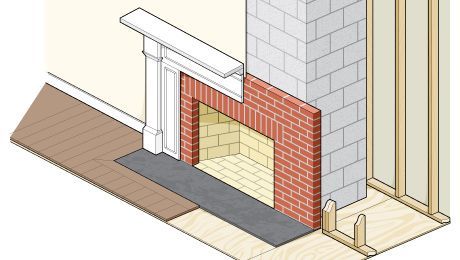

Prefabricated metal chimneys (whether insulated or not) have become almost universal for use with woodburning appliances. When we installed one, we thought, like most people, that our $20-a-foot expenditure was a lifetime investment. It hasn’t been for us — after two years we have already had to paint the exposed pipe, which was badly corroded (in an admittedly severe coastal environment). We have heard that metal chimneys can be badly damaged by undetected chimney fires. With many builders installing them in hard-to-reach places, it seems that the alternative of terra-cotta chimney liners set in standard 16-in. by 16-in. by 8-in. concrete chimney blocks is a safer and more permanent choice. The cost is comparable or less, the units self-aligning, and the blocks can be tied together with rebar for earthquake resistance.

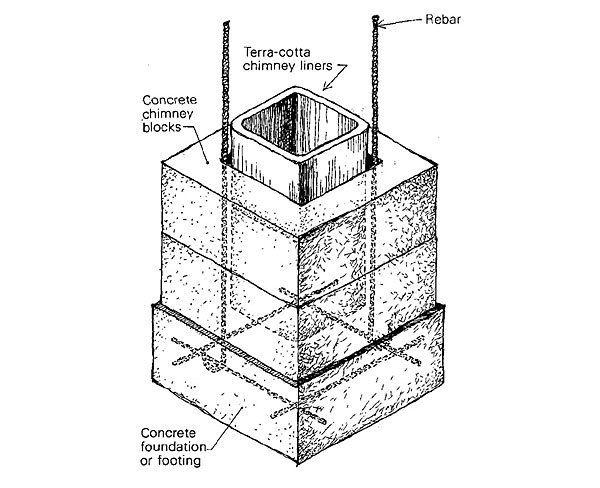

Flue liners and chimney blocks vary in size from location to location, but the local sources probably make compatible blocks and liners. The blocks around here are as shown in the drawing. Liners are usually started 4 in. above the bottom so they align each chimney block as it is laid.

Depending on local codes, earthquake and wind conditions, and the height of the chimney, it’s usually wise to run 1/2-in. rebars up from the footings to the top of the chimney on opposite diagonal corners and grout them in place. Usually 4-ft. to 5-ft. rods are as long as is comfortable to work with. Be sure to overlap them 20 diameters (10 in.). It is also advisable to tie the chimney to the ceiling and roof structure with steel straps, leaving at least a 2-in. clearance to combustible materials.

Tom Bender, Nehalem, OR