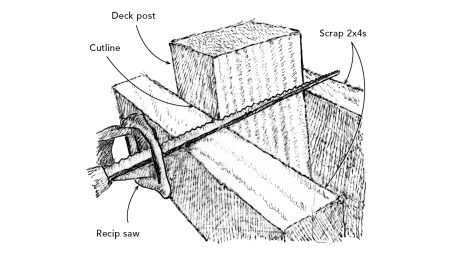

One of the most essential remodeling tools is the reciprocating saw, but remodeling work is very hard on their blades. Here are two tricks I use to prolong blade life.

First, I use 12-in. flexible blades whenever possible and do the cutting with the teeth closest to the tip. When the teeth wear down, I simply clip off the worn portion of the blade with tin snips and go back to work.

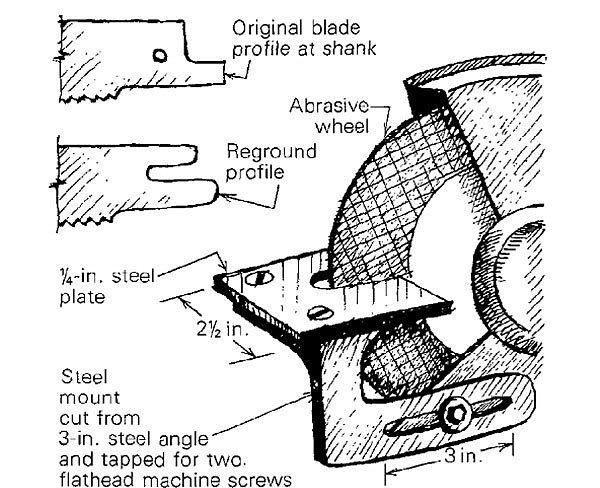

Second, and more important, I reshape broken shanks using a metal-cutting abrasive disc mounted on my bench grinder as shown in the drawing. Outline the shape of an original blade on the broken shank and grind away the excess metal with the abrasive disc until the new shank fits snugly inside the saw’s shoe. Then cut a slot in the blade just wide enough to accommodate the pin and retaining screw.

I’ve found innumerable uses for the bench grinder with this wheel installed. It will accurately cut a variety of materials from spring-steel roll pins to rubber hose. A work of caution: check the r.p.m. rating for the blade and the grinder to make sure they are compatible.

Philip Zimmerman, Berkeley, CA