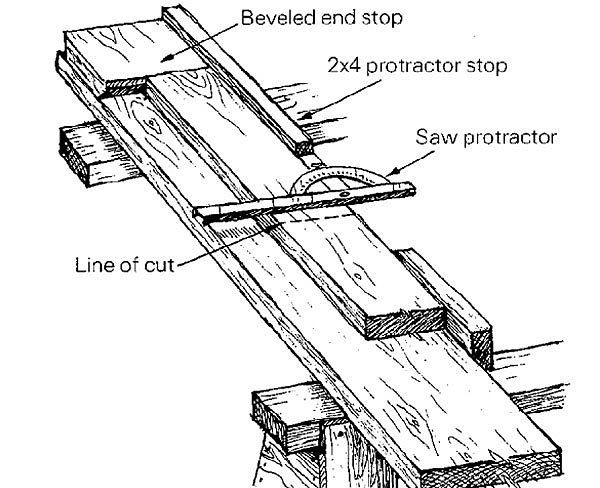

I seldom use radial-arm saws when I’m working on a job. They are expensive, difficult to move around and constantly out of adjustment. The alternative is to use the simple cut-off fixture shown in the drawing, a circular saw with a shoe that is parallel to the blade, and a $15 saw protractor.

The fixture can be made from 2x lumber of any width, and should be long enough to support the boards you are cutting. Attach a block across the face of the fixture at one end. Make sure that this end stop is perpendicular to the edge of the jig. This block should be backbeveled along the end grain on the working side of the jig to prevent sawdust buildup when it’s in use. A 2×4 block can then be nailed to the side of the fixture, with the bottoms flush. This is the protractor stopblock. It should be long enough, with the additions of the protractor arm length and the width of your saw shoe, to produce the cut-off length that you want.

Butt the piece to be cut against the end stop, set the protractor across the board and against its stop, and run your circular saw against the leg of the protractor. This method will produce fast, clean, accurate and repeatable cuts of any angle for everything from joist blocking to finish work without measuring and squaring each board.

If you are production-cutting several lengths, nail protractor stops in several locations along the length of the fixture. Clamping the stop is faster if only one or two cuts are needed at that length.

Ron Davis, Novato, CA