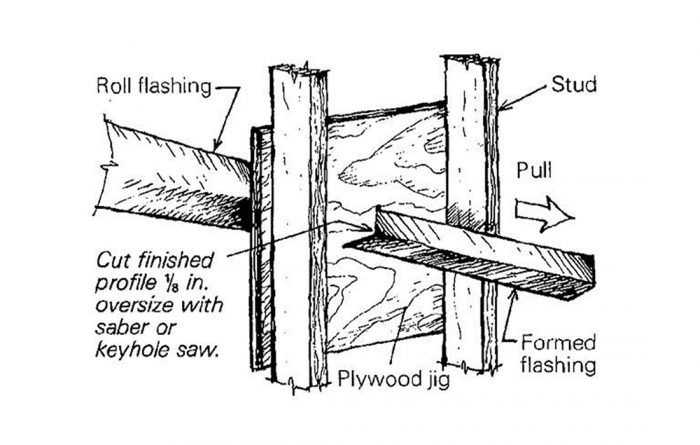

Bending your own flashing on site usually produces wavy, crinkled pieces of sheet metal that make you wish you’d had them made up at a shop. Here’s a fixture you can make on the site that produces near-perfect results.

Using a jigsaw or keyhole saw, cut the fullsize cross section of the flashing you want to make into a plywood scrap that’s at least 18 in. across. Nail the plywood across the studs of an unsheathed partition at chest level. Then cut a piece of roll flashing to length and insert it into one side of the cut in the plywood. With one person pulling and another supporting and feeding the flashing, this fixture makes the job easy.

—Mick Cappelletti, Newcastle, ME

Edited and illustrated by Charles Miller

From Fine Homebuilding #9

Fine Homebuilding Recommended Products

Fine Homebuilding receives a commission for items purchased through links on this site, including Amazon Associates and other affiliate advertising programs.

Hook Blade Roofing Knife

Shingle Ripper

Flashing Boot Repair

View Comments

This isn' the first time this tip is recycled, but it's a good one.

Thanks, very timely for me!