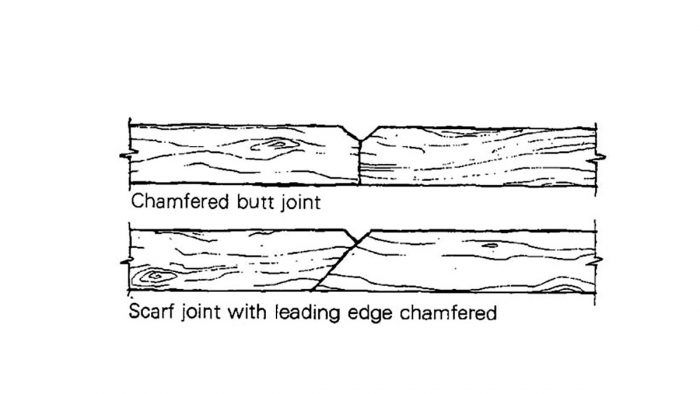

I’ve come up with a scarf joint for the board ends of paneling that gives a V-groove appearance on the end grain (see drawing). It has several advantages over a chamfered butt joint. I make an ordinary scarf joint and chamfer the leading edge. This saves the step of the second chamfer, and it conceals the gap between the boards.

—Ezra Auerbach, Lasqueti Island, None

Edited and illustrated by Charles Miller

From Fine Homebuilding #9

View Comments

I don't see how this would save any steps. The chamfered butt joint requires one cut on each board. The scarf joint requires one cut on one board but two cuts on the other. I can see how the scarf joint would hide the gap better, but it doesn't save a step.

Well, the OP is correct: His method requires 3 cuts, whereas the other method required each stick to be cut to length and then chamfered. That’s 4 cuts, but the real advantage of his method is that his joint is better concealed AND it draws down/captures the free end of the new piece for easier installation and better presentation. That’sa big win in my book.

Of course there are those whining A-holes who are going to complain about the hand drawings.... Nitwits have missed the “craft” part of our craft.

I've done this with rough siding on sheds--scarf pointing down to exterior. The profile hides waviness of imperfect boards and provides some drainage. Also handles movement better, you'll never see a gap even when they exist.