Synopsis: This is a thorough explanation of how to lay a strip hardwood floor. It covers subfloor choices and nailing schedules and the all-important issue of moisture content. Illustrations provide pointers on layout.

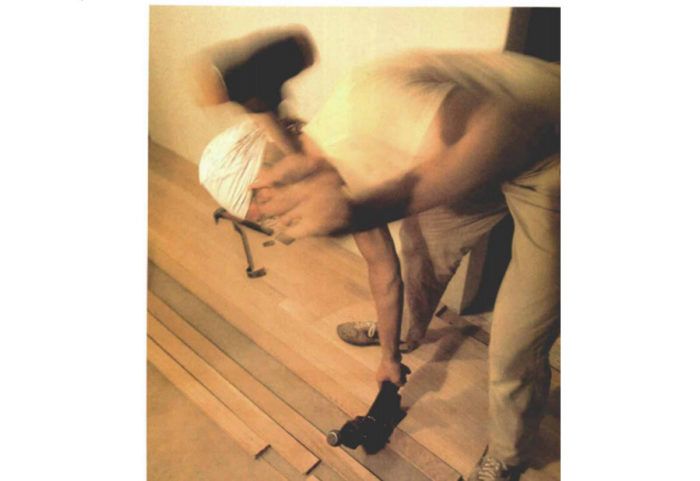

Putting down a hardwood floor is one of the few kinds of woodworking that can be classified as both rough and finish carpentry. Anyone who has installed a ¾-in. oak floor will attest to the brute force required to drive home the nails, and to the telltale evidence of every mistake. And since all the work happens at ground level, a floor mechanic spends half his time on his knees and the rest stooped over like a field hand.

Still, the bundles of hardwood flooring that get broken open for each job contain some of the most carefully graded and highest-quality building materials available today. It’s a pleasure to work with this stuff, and when wood this good is properly installed and cared for, it makes for a durable floor that can add a lifetime of color and warmth to any home.

Strip flooring

There are two basic types of strip flooring: tongue-and-groove (T&G) and square-edged. Some T&G strips are endmatched, which means they’re T&G on their ends as well as along their lengths. Strip flooring ranges from 5/16-in. to 1½-in. thick, and from ¾-in. to 3¼-in. wide. Here in the Northwest, most strip flooring is red oak, white oak, or maple, and the most common size, as it is throughout the country, is ¾-in.-thick by 2¼-in.-wide T&G. I like endmatched strips because they give the floor a bit more strength, and reduce bouncing where strips butt end to end between joists.

Hardwood strip flooring is further subdivided into random lengths and shorts, depending on quality. The better the grade, the fewer the knots, sapwood, and pinworm holes, and the longer the strips. For instance, the best grade of oak is called clear, and the strips are at least 1¼ ft. long, averaging about 3¾ ft. They are usually flatsawn, but the more attractive quartersawn strips can be special ordered. The poorest grade is #2 common. These strips, which average 2¼ ft. in length, have knots, checks, and worm holes. When you order any grade, add 5% to 10% to allow for waste.

Precautions

Have your flooring delivered at least three days before you install it, and break the flooring bundles open so the boards can adjust to the ambient moisture. If the floor is going into a new house, make sure the place is sealed up, and that all masonry, plaster, drywall and other wet-process work is completely dry. Three weeks before the flooring is to be delivered, turn up the thermostat to your typical setting to help dry things out. If there is too much moisture in the house when the floor is installed, the floorboards will shrink when the humidity drops, and you’ll get ugly gaps between them. Moisture can also come up through the subfloor, so make sure the basement is dry and well ventilated.

For more photos, drawings, and details, click the View PDF button below:

Fine Homebuilding Recommended Products

Fine Homebuilding receives a commission for items purchased through links on this site, including Amazon Associates and other affiliate advertising programs.

Anchor Bolt Marker

Original Speed Square

100-ft. Tape Measure