In response to Eric Rekdahl’s method for cutting curves in thick timber with a Sawzall (see Cutting curves in big beams), I have an alternate method to suggest. It was devised after rejecting several other approaches, including the portable bandsaw, which had insufficient throat for the cuts we wanted to make.

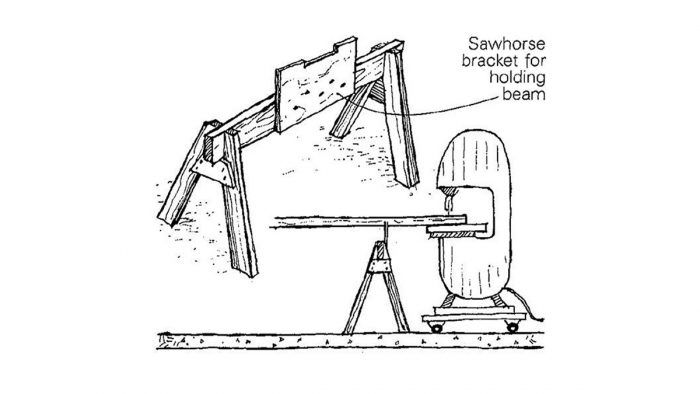

Like Rekdahl, I also had to make decorative curved cuts in large beams. I trucked the beams to my shop and set up my bandsaw on a dolly mounted on casters. Then I cut a pair of plywood supports with shallow notches the width of the beams, and spiked them to the 2×6 crossbars on a pair of sturdy sawhorses as shown above. The bottoms of the notches were placed at the height of the saw table, and the horses were spread apart to support the beams securely.

After marking, the beam was placed on the horses, and the bandsaw was rolled up to the beam to make the cut. Since the dolly could readily be moved in any direction, I found that I could direct the blade accurately through the wood, albeit using a spread-legged stance and bear-hugging the saw.

The first wheels that I used were the ballbearing type that are set in their own chase. But these tended to collect sawdust, causing the balls to stop rolling. I ended up using offset rubber wheels, which worked much better.

With a 3/8-in. blade, it was easy to cut the 5-1/2-in. diameter semicircle I had drawn on the beam. I had an assistant along that morning, but the setup was so stable that he had little to do beyond catching the cut pieces as I rolled the bandsaw around the beam.

—Robert Gay, Seattle, WA

Edited and illustrated by Charles Miller

From Fine Homebuilding #17