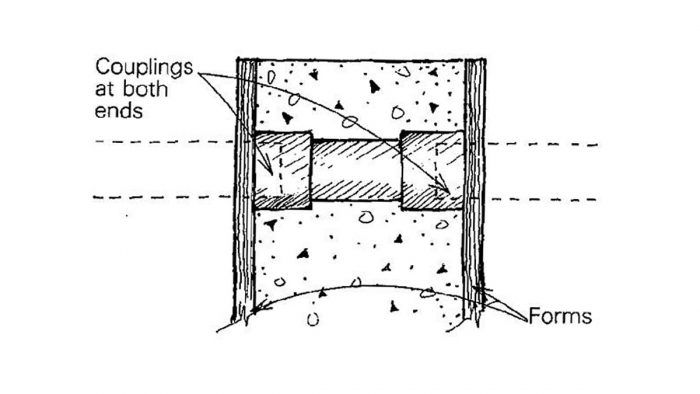

Running pipe or conduit through a poured concrete foundation wall with no gaps to patch and without cutting holes in the forms sounds too good to be true until you’ve tried this trick. Cut a piece of the pipe you need and attach couplings to both ends so that the total length of pipe plus couplings exactly matches the thickness of your wall, as shown in the drawing.

This unit will then fit snugly between the forms, and can be wired to the rebar and spreaders at the top of the forms to keep it in place during the pour. When the forms are pulled away, you have a coupling embedded on each side, flush with the wall and ready for another length of pipe.

—D. A. Fleury, Curlew, WA

Edited and Illustrated by Charles Miller

From Fine Homebuilding #27

View Comments

This is not a method that would work in Southern California. We find it smart to wrap and cushion any pipes penetrating the concrete so they are less likely to snap during a "seismic moment." A little modification of the author's method would probably work here where every day is Earthquake Appreciation Day.

This method, while sensible for the foundation guy and interior connection(s), would not be wise for exterior conditions. Backfill against a foundation is seldom compacted uniformly, resulting in subsidence over time. Here in CT that longtime subsidence can be 6" or more, which can result in downward forces on the exterior connected pipe.

In addition, concrete is rarely fully consolidated which can lead to water intrusion around the embedded pipe.

I would prefer the larger diameter sleeve thru which the pipe can be installed. The annular space would then be filled with an easily compressed sealant.