Sidewall Shingling

For that authentic Cape Cod look and low maintenance, you can't beat cedar siding.

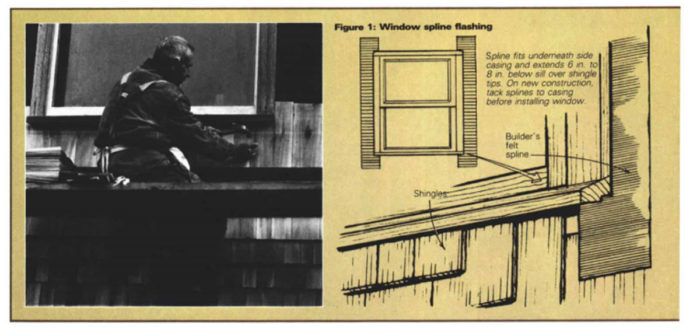

Synopsis: This is a guide to installing cedar shingles on the side of a house, a process that in pre-pneumatic days required only a few simple hand tools and some know-how. Illustrations explain basic rules of thumb, and the text adds traditional details. A sidebar explains how to estimate materials.

Sidewall shingling has always been one of my favorite carpentry jobs. It requires a good measure of skill, repetition and precision, all steeped in cedar aroma. And you can watch the house’s character emerge with each new course.

Shingles aren’t the cheapest siding material you can use, and they take longer to apply than most other types of siding. But the reward for a good shingling job is in looks and longevity. A good grade of cedar shingles, white or red, will last a long time with no maintenance. The first house I shingled 40 years ago still has many years left in its siding, which has weathered to a beautiful grey.

Tools

Nothing fancy here. A hammer and utility knife are my basic tools for most shingling jobs. For fastening shingles, power staplers are okay, and you’ll see a lot of them in use wherever tract houses are going up. The trouble with using these tools is that speed sometimes overshadows quality. There’s a real difference between shingling fast and shingling well. Preparation, layout and application are more important than speed if you want a good-looking job that will last for many years.

A shingling hatchet can be used in place of a hammer and knife. The hatchet’s waffle-face head is less likely to glance off a nail onto a finger when the nailhead has a gob of zinc left on it from the galvanizing process. Only hot-dipped galvanized shingle nails should be used for this kind of work, and the length I use is 3 in.

The blade of the hatchet is for squaring and trimming shingles. I find that a utility knife does this better, though, and it’s safer and easier to carry around. For cutting across the grain, a small handsaw is better than a knife. I use a 10- point (10 teeth per inch), 20-in. crosscut saw.

A chalkline, a tape measure and a level are three other essential tools. They’re all used for setting course lines. I use blue chalk because red stands out like a sore thumb, especially if you’ve snapped a course line too low. There’s no need for long measurements when you’re shingling, so a 12-ft. tape is fine.

I keep nails, a utility knife and a tape at my waist in a two-compartment canvas nail apron. A lightweight holster carries the hammer. The level hangs on a nail in the end of the staging planks, and I keep my saw handy by shoving the blade up underneath a course of shingles. The chalkline just hangs around on the staging.

Short walls can be shingled from staging planks set on sawhorses. Taller walls and gable ends require wall brackets, pump jacks, or push brackets. For reshingling work, pump jacks or push brackets are ideal because they don’t require punching a hole in the wall for support. For new work, I prefer wall brackets because of their simplicity and security.

For more photos, drawings, and details, click the View PDF button below: