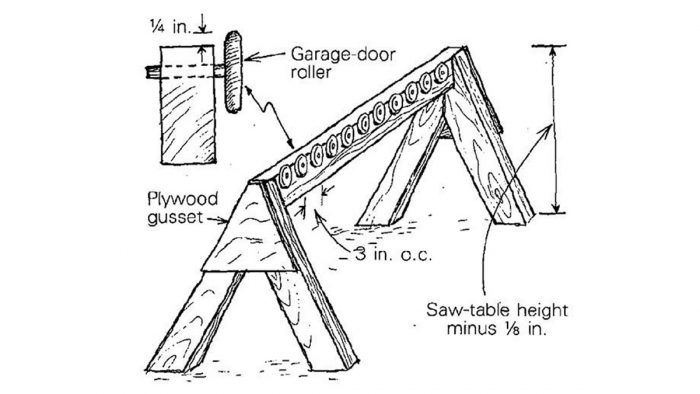

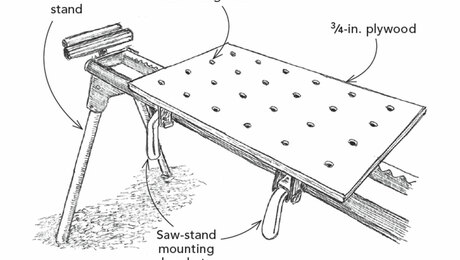

One of the most awkward operations to perform in my tiny one-man cabinet shop is crosscutting a full sheet of plywood. The outboard roller stand shown in the drawing has made this task a lot easier for me. The roller stand is essentially a sawhorse with a row of garage-door rollers mounted 3 in. on center across the length of the crossbar. I made my stand out of 2×4 stock, screwed and glued together for rigidity and braced at the top with plywood gussets. With one of these stands beside my tablesaw, I can push a sheet of plywood through a cut with little resistance.

—Lewis A. Locke, Ellenburg, WA

Edited and illustrated by Charles Miller

From Fine Homebuilding #29

View Comments

I'm sure it would also work adequately for the occasional sheet of man-made material if the wheels were simply cut out of ply with a hole saw. No need to pay for expensive rollers.

I have roller stands. Yes, gotta have something. Harbor Frieght have 1" roller bearings for $2@, Rockler has 5/8" and 1" for $4 & $5 respectively. Beer breweries love the HF ones for moving cases around the brewery. They buy them all out all the time.

Now if I were to make a device like this, I would use ball transfer rollers. That way, the orientation of the stand would not be directional. See: https://www.mcmaster.com/5674k1

With my roller stand, I have found that it is to be perfectly aligned otherwise the material will drift away from the saw fence. I am going for ball rollers.