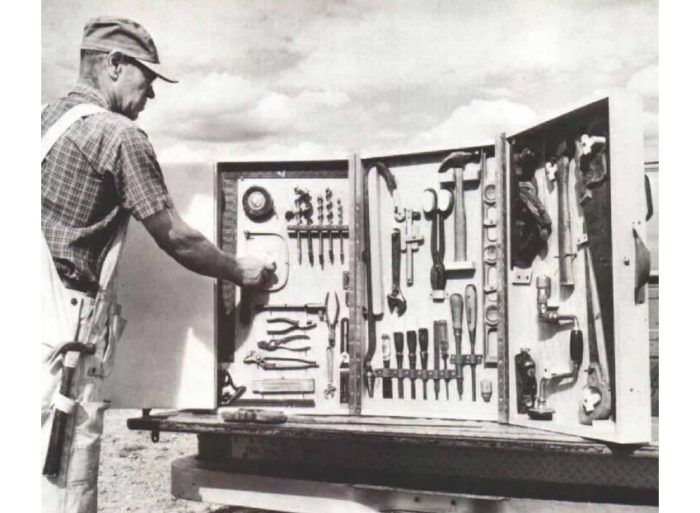

Synopsis: Most anyone who works with tools will build at least a toolbox or two. This is a look at several no-frills options, not the dressy products of cabinetmaking schools but the workaday boxes you put in your truck at the end of the day. The author’s observations will help with the design.

Over the years I’ve seen plenty of toolboxes. Most of them are variations on several basic designs that have stood the test of time. Now and again I build a new toolbox, either to replace one that’s worn out or because I think I’ve got a better design.

Before looking at particular toolbox designs, it’s important to acknowledge some general design guidelines, The most important requirement of a good toolbox is capacity. It’s got to be able to hold all, or at least most, of the tools for a specialized or general job. It has to be spacious and durable without being so unwieldy that you can’t move it comfortably from place to place. A toolbox doesn’t merely store tools; it protects them when they’re not in use. This means that edge tools like chisels and planes shouldn’t be allowed to knock around in the box. Levels, saws and files need similar protection.

Tools should be readily seen, easily accessible when they’re needed and conspicuously absent when you’re packing up at the end of the day. And last, a good toolbox makes a good impression. If you’re on a job with new clients or among unfamiliar carpenters, your toolbox is a resume of sorts. Sure, you can carry your tools in a 5-gal. joint-compound bucket, but chances are your clients or your fellow carpenters will spend a lot of time looking over your shoulder.

The open shoulder box

With today’s widespread use of portable power tools, the framing carpenter might get by without an open shoulder box. In the old days, though, these simple toolboxes were standard equipment. Typically narrow and 2 ft. to 3 ft. long, the open shoulder toolbox has a closet-pole handle that extends the full length of the box. The ends of the box are higher than the sides to keep the handle up out of the way so that tools can be picked up and replaced quickly. These boxes are meant to be moved around a lot, so they’ve got to be ruggedly built and symmetrically proportioned in case you need to put the thing on your shoulder and climb a ladder. Handsaws, pencils, hammers, a prybar, a level, try and framing squares, a few chisels, a chalkline and a tape measure or folding rule are some of the tools the average shoulder box is meant to hold.

To keep tools from banging into each other, most carpenters build a few compartments into these boxes. Kerfs for handsaw blades can be cut into one end of the box and the saw handles can protrude outside the box, or you can simply make the box long enough to accommodate the full length of the saw. In the better shoulder boxes that I’ve seen, there is a long compartment for saws on one side. And there are several lower compartments and one or more small, shallow boxes that rest inside the box on top of the lower partitions.

For more photos and details, click the View PDF button below:

Fine Homebuilding Recommended Products

Fine Homebuilding receives a commission for items purchased through links on this site, including Amazon Associates and other affiliate advertising programs.

Reliable Crimp Connectors

Spyder Stinger Spade Bit

Cadex 18-Gauge Brad Nailer (CB18.50)