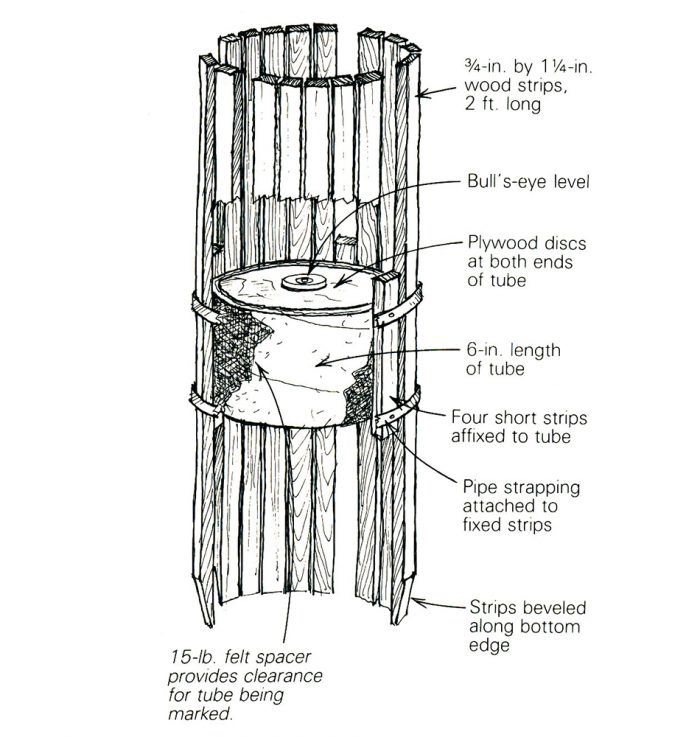

Constructing a deck on the rocky coast of Maine presents the problem of accurately and quickly cutting tube forms so that they conform to exposed, irregular bedrock surfaces. Good-looking, strong concrete piers require a leak-free contact between the form and the rock. To meet these requirements, I constructed the contour gauge shown in the drawing. Pressed against the rock and made plumb with the aid of its bull’s-eye level, the slats of the gauge can be tapped to conform to the contour of the rock, and this line can be quickly transferred by inserting the tube to be cut into the gauge, and tracing around the bottom of the movable strips. I built this gauge from scrap materials in a couple of hours, and it easily paid for itself in one job.

Ian R. Walker, Princeton, NJ

Edited and Illustrated by Charles Miller

From Fine Homebuilding #31

Fine Homebuilding Recommended Products

Fine Homebuilding receives a commission for items purchased through links on this site, including Amazon Associates and other affiliate advertising programs.

FastenMaster Screw Bolt Fastening System

Standard Marking Chalk

Lithium-Ion Cordless Palm Nailer

View Comments

Dude, that is awesome! I want to buy you a beer next time I'm in NJ!

I may be using this tip to set piers on bedrock for a workshop that I'm building for myself up in northern NY. Adding a magnetic compass to the jig could help with orientation once the tube is cut. (Or just mark the lowest point. . .)

Very ingenious! It require a bit of real accuracy when cutting the internal cardboard tube and the plywood disks to insure that the ends are square to the centerline of the pier.

Worth noting - I have found that Hilti's rigid spray foam works as an amazing seal between the top of an irregular surface and the bottom of a concrete form. Fill the gap, let the foam expand, and cut away any that protrudes into the space on the concrete side.

Shouldn’t the footings be poured first?