Building a Cantilevered-Tread, Spiral Staircase

Smart layout and design allowed for the construction a circular stair around a 20-ft.-long piece of yellow cedar driftwood.

Synopsis: This article explains how the author made a circular stair around a 20-ft.-long piece of yellow cedar driftwood. Positioning of the treads was done in place, as was construction of the curving hand rail. The article contains useful tips on layout and design.

Throughout the Saks house there is a feeling of openness, and we wanted the spiral stair to the bedroom and lookout tower to echo this feeling. We wanted it to be a structure with delicate lines, unencumbered by external support systems and limited to the tones and textures of wood. For me, each aspect of this 6-ft.-dia. spiral construction was a challenge, always an adventure, and often a headache. More than once I considered selling my tools and opening a restaurant

Layout

The central support for the staircase is a 20-ft.-long yellow cedar driftwood log, about 1 ft. in dia. at the base. As a structural member of the house, the log was standing when I came on the scene, and it had to be laid out and worked in place. It was neither completely round, nor straight. Consequently, the tread mortise positions had to be projected inward from a 6-ft.-dia. imaginary cylinder symmetrically enclosing the assumed centerline of the log. Since the position of the outside end of each tread was fairly critical, individual tread lengths had to vary by an inch or two depending on the warp of the log. The entire layout for the tread positions had to be completely independent of the log, with the projected mortise positions falling arbitrarily on the log’s uneven surface.

The rise of each step is 7.3 in. To climb the distance from the ground-floor landing to the bedroom landing, 13 treads travel an arc of 292° , one tread per 22°. This let me find the centerline of each tread, and ignore the overlap of the treads, which was an inch on each side.

To get the mortise positions for the treads, I made a flat plywood pattern of the 292° arc. I drew lines on the pattern dividing it into 13 segments, and made a mark for the centerline of each segment. Then I cut out the center of the pattern so it would fit around the base of the log column, and positioned it on the floor where the first tread would start, minus the overlap. I put some index marks on the pattern and the column for future reference points, then I transferred the centerlines of each tread onto the log using a pencil and a plumb bob. I marked the rise intervals on a story stick and transferred them as top of tread lines to the corresponding tread centers already scribed on the pole.

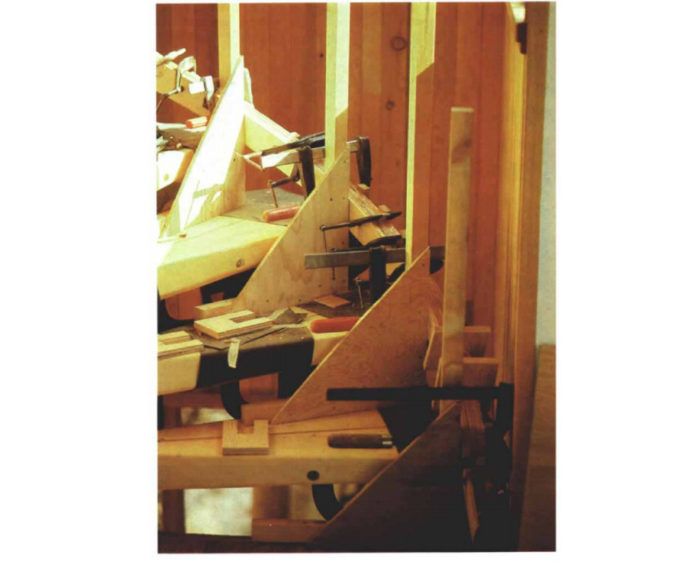

Tread construction

Each tread is completely self supporting. They cantilever from the pole on brackets made from steel bar stock welded to a butt plate. A piece of threaded rod welded to each butt plate extends through the log. The butt plates sit in routed mortises, ranging in depth because of the uneven surface of the log.

For more photos and details, click the View PDF button below:

Fine Homebuilding Recommended Products

Fine Homebuilding receives a commission for items purchased through links on this site, including Amazon Associates and other affiliate advertising programs.

Original Speed Square

Smart String Line

Anchor Bolt Marker