From Boulders to Building Blocks

How a traditional stonemason quarries and dresses sandstone.

Synopsis: This is the story of Benny Soto, a California stonemason who specializes in working locally plentiful sandstone into regularly shaped pieces that can be used to build walks, fireplaces, and walls. Mainly an account of his work habits, the article also offers tips on the practice for anyone who wants to try it himself.

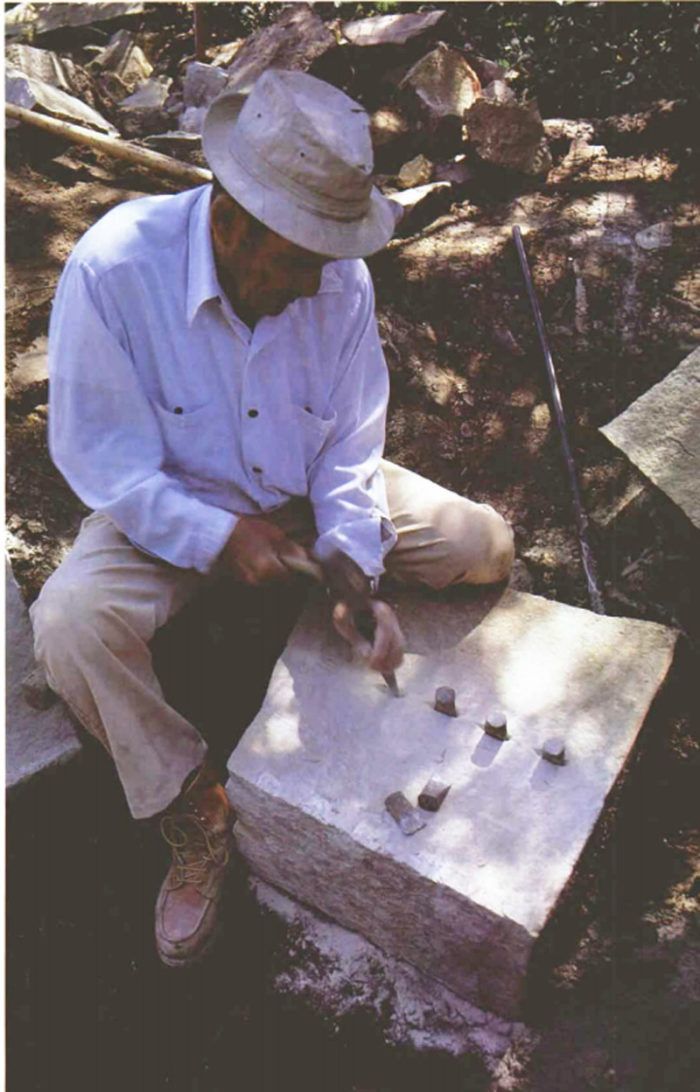

Benny Soto doesn’t have to look at the chisel anymore when he dresses a block of sandstone. His hammerhead instinctively finds the butt of the chisel, sending a steady clink, clink, clink ringing around the building site. The stone chips fly about, as he transforms another ordinary rock into a hand-tooled flagstone.

It wasn’t always this easy for Soto to hit the chisel butt dead center. Sixty years ago, when he moved to Santa Barbara, Calif., from his native Guadalajara, Soto started his masonry career by lugging stones and digging ditches for a group of Italian stonemasons. Sensing that he had more to offer than a strong back, his boss urged him to learn the stonemason’s trade. Soto agreed to give it a try, anything had to be better than lifting and toting rocks about all day, broken only by bouts of ditch-digging.

But the shift from hard labor to skilled craft wasn’t without difficulty. Many of Soto’s unpracticed mallet strokes hit the chisel butt slightly off center. The hammerhead would glance to the side, and the big knuckle on his left hand would take most of the shot. He hit his hand so many times that he developed blood poisoning, and he nearly lost his resolve to learn the trade during the two weeks that it took him to recover. But the thought of going back to the ditches was a powerful incentive, and Soto stuck with it.

The on-site quarry

Over the last 60 years, Soto has built walls of random rock, flagstone patios, fireplaces with squared-off sandstone blocks and baronial entryways topped with S-curved capstones. He quarries the stones himself, and given Santa Barbara’s notoriously rocky soil, he usually needs to go no farther for raw materials than any nearby foundation trench. Some of these virgin stones are the size of beach balls, others are as big as hippos. The big boulders are easiest to work, for the same reason that you get more uniform slices from a loaf of bread than you would from a biscuit.

Although electric and pneumatic drills and chisels are now available, Soto relies on the kinds of tools that stonemasons have used for centuries. He thinks that handmade work should look handmade, and power tools (besides being too noisy) take away some of the artisan’s control. Solo’s tool bucket contains steel wedges, cold chisels and a 4-lb. hammer. The hammer has a hickory handle, which absorbs some of the shock of hitting the chisels. If the handle gets slippery, Soto roughens up the hickory on the edge of a stone. If a handle breaks, he shapes a new one to the right contours, using a piece of broken bottle as a scraper.

For more photos and information on how to build from sandstone, click the View PDF button below.

Fine Homebuilding Recommended Products

Fine Homebuilding receives a commission for items purchased through links on this site, including Amazon Associates and other affiliate advertising programs.

Smart String Line

100-ft. Tape Measure

Plate Level