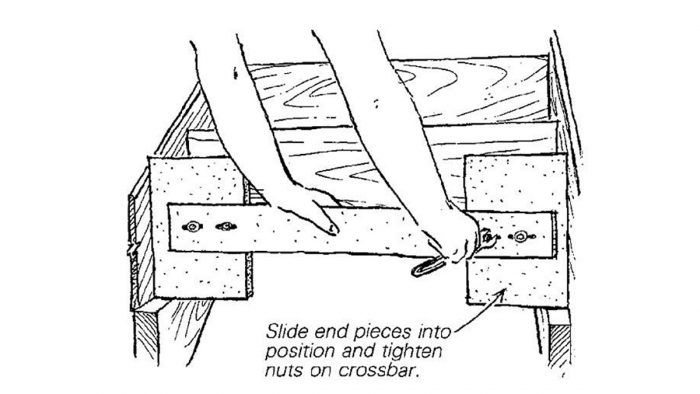

It would be nice if the treads and risers in a site-built stair could all be the same, but the vagaries of wood-frame construction usually mean that uniform lengths and 90° angles are as often exceptions as they are rules. To get accurate measurements for treads and risers that vary by just a little bit, I use the marking gauge shown in the drawing. It consists of two end pieces and a crossbar, all made of 1/2-in. particleboard. The end pieces are secured to the crossbar with nuts, washers and four 1/4-in. flathead machine screws, which protrude through oblong slots in the crossbar. The slots allow the end pieces to be moved in and out until they make a snug fit with the skirt boards — even if they are a bit out of square. Once the fit is right, I tighten the nuts and transfer the entire gauge to the riser or tread stock, where I can mark the exact layout without making any tedious measurements.

—James M. Westerholm, Seattle, WA

Edited and illustrated by Charles Miller

From Fine Homebuilding #35

View Comments

I use this same jig and then clamp it to my tread or riser and use a router bit with a bearing cut these pieces.