Synopsis: This article is an interesting look at how nailed connections in residential construction can be engineered for specific loads and applications. It provides useful information for making sure that structurally important but non-routine connections perform as expected.

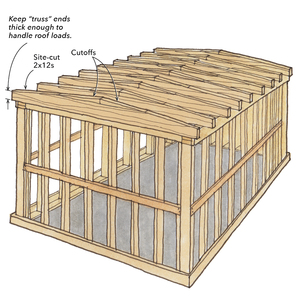

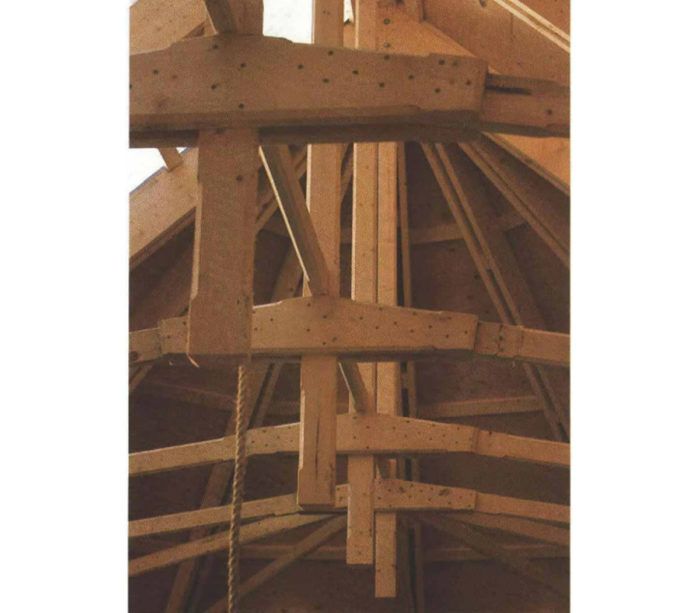

The nailed connections in an ordinary house frame conform to a chart found in most building codes. Most designers and builders seldom give them a second thought. But many building designs contain connections that aren’t of the ordinary sort — columns to major beams, connections in trusses, splices in roof ties and unusual intersections in floor framing. And many times a nailed connection must be designed for some non-standard project such as a footbridge, a large wind-buffeted sign, a piece of playground equipment or a temporary exhibit structure.

Too, a builder often designs scaffolding, concrete formwork and other one-of-a-kind temporary structures in which nailed connections must be counted on to carry substantial loads without failing. In any of these special situations, it’s reassuring to know that nailed connections can be engineered with the same degree of precision as connections made with bolts, lag screws and split rings.

All things considered, nails are the most versatile fastening devices available for wood construction. They are inexpensive and lightning fast to install; they are always available in the sizes that we use most; and they are less obtrusive than bolts and lag screws. As a bonus, nailed connections are a lot less complex to engineer than bolted or screwed connections.

General considerations

The design of nailed connections is governed under all of the major building codes by the National Design Specification for Wood Construction, which I will refer to in this article as the NDS. It’s the bible of engineering practice for wood construction, and is published by the National Forest Products Association. You may find it worthwhile to become familiar with this book if you design wood buildings, because it covers calculations for beams, joists, columns, tension members, glue-laminated wood, and connections using bolts, wood screws, lag screws and split rings, as well as nails.

But to use the NDS effectively you need to have had a course or two in structural engineering. For this article, I have summarized its provisions on designing connections using common nails, and have tried to put its guidelines into a form that’s easy to use.

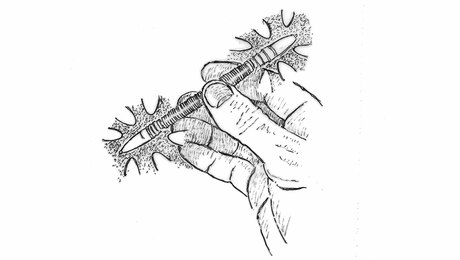

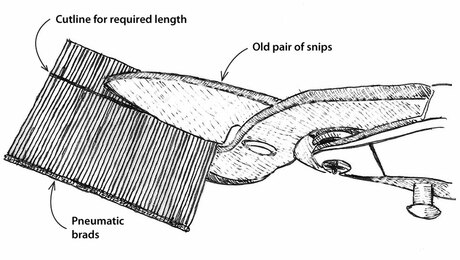

There are some things to keep in mind when you set out to design a nailed connection. Common nails, box nails, spikes and threaded, hardened-steel masonry spikes and nails can all be used in structural connections under the NDS. But finish nails can’t be used as structural fasteners.

Box nails are weaker than common nails, so if you want to design a connection using box nails you will have to refer to the NDS, as you will for common spikes, which have somewhat higher values than those given here for common nails. Vinyl-coated sinker nails don’t yet appear in the NDS, so we have no firm basis for designing with them. For this article, threaded hardened steel spikes and nails have the same load-carrying capacities as common nails.

For more photos, illustrations, and details, click the View PDF button below:

Fine Homebuilding Recommended Products

Fine Homebuilding receives a commission for items purchased through links on this site, including Amazon Associates and other affiliate advertising programs.

Leather Tool Rig

Protective Eyewear

Sledge Hammer