Pickup-Truck Tool Storage

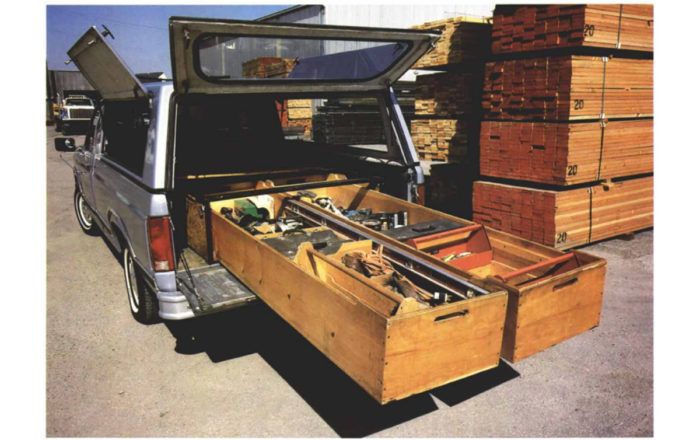

Long sliding drawers let a builder get to his tools, even under a stack of plywood.

Synopsis: A builder who spends a lot of time traveling from one job to the next details his solution for tool storage: a pair of 8-ft. long drawers that turn his pickup truck into a “rolling hardware store.” This is another take on solving a problem many builders face.

I’m a builder who works on a variety of jobs at different locations during a typical week. As a consequence, my pickup truck is a rolling hardware store, and I often need to haul around a stack of building materials to boot. Anyone who’s had to carry both tools and materials in the same pickup knows what kind of problems can result — the tools inevitably end up under a pile of lumber or drywall, inaccessible when they are needed.

Because I carry so many tools, I want them to be safely locked up inside a shell that covers the bed of the truck. The shell eliminates the easy addition of a lumber rack, so I needed some other way to carry tools and materials that allowed ready access to both.

My solution is a simple one. I keep my tools in a pair of 8-ft. long drawers made of 1×14 knotty pine boards and plywood. The drawers are subdivided into compartments for various kinds of tools and supplies. Over the years I have noted which tools I use with the greatest frequency, and I keep these — my carpentry tools and tool belt, extension cords and general purpose hand tools — in the compartments closest to the tailgate. In the middle bays I keep three toolboxes devoted to door-jig equipment, socket sets and wrenches and miscellaneous hardware. In the back bay of one drawer I keep my power tools, and in the other I stash painting equipment, shim stock, nails and other fasteners. To speed up loading and unloading, I keep related tools in lift-out trays or toolboxes that nest into the compartments.

The drawers fit into a steel and plywood carcase that is covered with four plywood lids. If I don’t have a load of cargo resting on the plywood, I can get at the drawer compartments through the doors in the side of the shell. Notches cut into the plywood sides of the carcase allow me to sneak a hand under the plywood lids so that I can lift them away to gain access to the tools.

If, on the other hand, I’ve got a load of materials resting on the cargo platform, I can pull the drawers out so that about 6 ft. of their substantial length is readily accessible. When the drawers are extended this far, their inboard ends bear on one of the steel crossbars, which resist the considerable upward thrust of the fully loaded drawers.

A steel framework

A local welding shop fabricated the steel skeleton of my storage system. The outside dimensions of the frame are 49 in. by 97 in., which gives me a little wiggle room on the top of the platform for loading 4×8 sheets of plywood or other material.

For more photos, drawings, and details, click the View PDF button below: