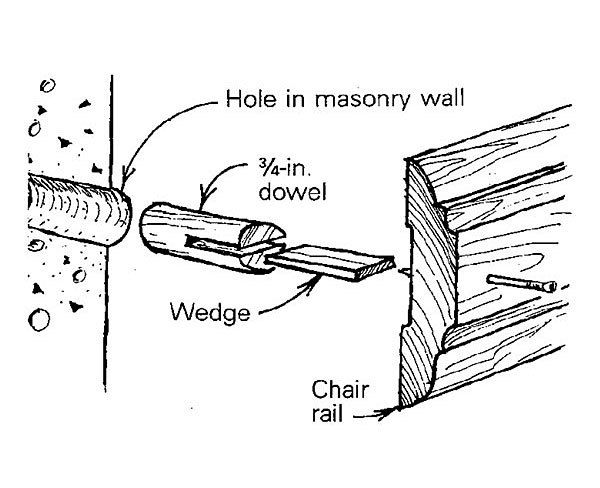

The drawing illustrates the method that I use to apply trim pieces, such as chair railings, to a concrete, brick or block wall. I do it this way because it allows me to use finish nails to secure the work to the wall. Then the nail holes can easily be filled to match a natural or stained finish.

First I drive nails into the railing so that their tips just begin to emerge on the backside. Then I hold the railing in place on the wall and drive the nails far enough to make marks. Next I drill -in. holes in the masonry, using the nail marks as centerpoints. I fill each hole with a piece of 3/4-in. dowel that has been kerfed on one end with a bandsaw. If I’m working on a concrete block wall with open cells, I make sure that the dowel is long enough to bear against the far inside wall of the block.

Once the dowels are wedged in place and trimmed flush with the wall, I affix the railing to the wall by driving the nails into the dowels.

—Jim Stuart, Covina, CA

Edited and illustrated by Charles Miller

From Fine Homebuilding #47

View Comments

The mechanics of the described system are structurally sound. The issue I would like to know is how well the wood dowels stand up to constant concrete contact. Hardwood dowels fair better than softwood (?) but the constant battle with moisture-induced swelling and rotting would make me wonder when this would fall off the wall, years decades?

With respect to ktkcad's comment, I would think that most interior CMU or concrete wall surfaces remain relatively dry. Besides, nothing lasts forever.

I had a similar challenge in anchoring small low-voltage wires to my concrete foundation wall. I had some small dowels on hand, so I drilled small holes into the concrete, anchored the dowels into the wall with epoxy, trimmed them flush and then used small cable clamps nailed into the dowels to secure the wiring.

This is a tried and true method. In my house built in 1900, I found dowels in the basement walls (soft brick) used to secure firring strips for paneling, and in the concrete floor I found dowels for securing the bottom plate of partition walls. The dowels were sound—not rotted or decayed at all. They may not have been original to the house, but they were very old.

Living in a country where there are vastly more masonry walls than wood ones, I’d like to share one method of fastening baseboards – screws driven into plastic plug anchors. As a matter of fact, I use screws even when the base material is wood because the screws make it easy to remove and reinstall the baseboards – for example when floors are sanded, walls painted, carpet replaced or when there are mice in the subfloor begging for some poison.

What is really handy about the screw-fastened baseboards is that there is easy access to the empty channel behind and below the baseboard. I regularly place conduit or cable in this space.

The screws available to me come in white and various shades of brown to roughly match various natural woods. The esthetics? If you look for the screw heads, you will see them and some people – especially installers – will object to this. The casual observer will never notice.

It may be a matter of taste, but I really fail to see the benefit of pretending that the trim has been put there by the Almighty.