Synopsis: In this second story on the subject of building barrel vaults, an architect offers a somewhat technical explanation of how he built an addition with a barrel-vaulted ceiling made of 36-ft.-long wood I-joists and ribs made of cold-rolled steel channel.

Drawing a simple arc on an elevation can change the entire approach to the design and construction of a project. At least that’s what happened with the Gottlieb/Davis remodel. Dan Gottlieb and Peggy Davis had originally wanted a kitchen remodel and greenhouse addition to their house in Palo Alto, California. But after analyzing their programmatic needs, the existing residence, and site, as well as property values in the neighborhood, we agreed that a more extensive remodel was appropriate.

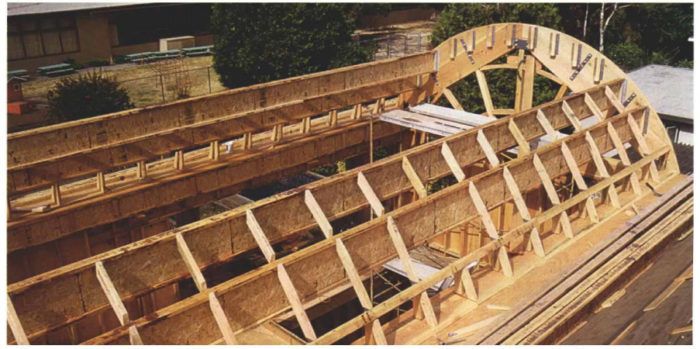

The general massing of the house took on the appearance of two row houses, each reflecting a different living zone. One became the private zone: the bedroom area with a pitched roof. The other was the public zone: living, dining, kitchen, sunroom, second-story library and a bridge to the other side. We jokingly referred to the public space as the grand hall. In the search to find a dramatic roof for the grand hall, I sketched a barrel-vault ceiling and changed the course of the project.

I submitted the barrel-vault design to Dan and Peggy as one of three proposals. They were apprehensive, but at my suggestion, they decided to build a scale model, and once they were able to visualize the design, the barrel vault became the obvious choice.

We knew that the complexity of building the vault would either deter some contractors from bidding on the project or would result in highly inflated bids. So after a thorough discussion, Dan and Peggy and I decided to build the project ourselves.

Design dilemmas

Conceptually, the grand hall is a basilica with a nave and side aisles. The aisle on the south became the entry, stairs, and sunroom. And the loads from the vault would flow through the wall to the foundation. The northern aisle, however, was problematic. Due to the constraints imposed by the floor plan, there were no walls that could take roof loads directly to the foundation. A typical strategy of using a curved truss at intervals to shape the vault would require a very large and heavy beam to carry the loads to the end walls. I had to find an alternative solution.

The elevations of the two end walls dictate the shape of the roof and interior space, so it seemed logical that the structure should span the length of the hall with loads flowing down through these end walls. The problem was to find a structural member that could span 36 ft. and yet be light enough to carry by hand. A glulam beam, for example, would have been too heavy.

The metaphor that the vault was, in effect, a floor of parallel joists in the shape of a circle, suggested that some form of lightweight wood truss could span the distance. After considering the cost and weight of various engineered components, I decided on wood I-beams with solid-lumber flanges and oriented strand-board webs purchased from Structural Development, Inc.

For more photos and details, click the View PDF button below:

Fine Homebuilding Recommended Products

Fine Homebuilding receives a commission for items purchased through links on this site, including Amazon Associates and other affiliate advertising programs.

Protective Eyewear

Short Blade Chisel

Portable Wall Jack