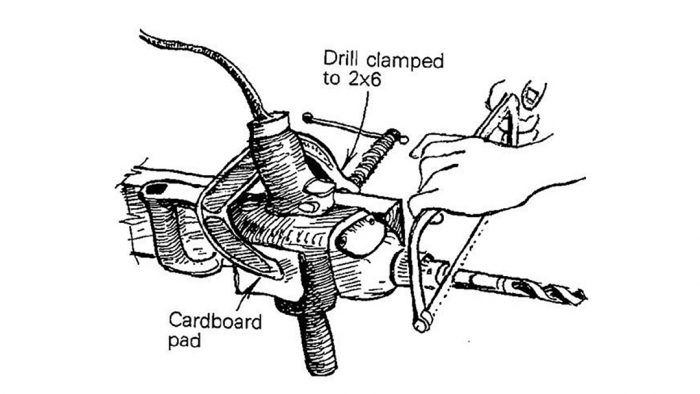

Recently I needed to shorten the shank of a 3/4-in. hardened steel drill bit. Depressed at the thought of all that time and elbow grease, I devised the method shown in the drawing. With the drill securely clamped to a 2×6, I adjusted it to its highest speed, pressed the lock-on button and let gravity and the hacksaw do all the work. A few drops of oil made for a cool cut.

—Dorothy Ainsworth, Ashland, OR

Edited and illustrated by Charles Miller

From Fine Homebuilding #54

View Comments

Great Idea, Dorothy, but I "Wouldn't" use the "Highest Speed" and I'd use a "Heavy Oil"(Over a Drip-Pan) and the Right Hacksaw Blade and "Move It" without "Too Much" Pressure. GREAT Job but I "Hope" everyone just "Goes Slowly," the Drill does the "Work".

Good idea with the drill Dorothy, but instead of using hi RPMspeed on the drill, I suggest eeeping it at low RPM for safety reason (when the drill is freed after cutting). Instead of ruining a hacksaw blade on your hardened drill steel, I suggest cutting safely the rotating drill bit with the friendly angle grinder. Best, safe and clean cut garanteed !

Agreeing with the safety of lower RPMs. If you ever had to clean up a shop where the lathe was set for wood when running an aluminum part you would understand. Metal, metal everywhere!