Installing Arch-Top Windows

How one builder supports the loads without a conventional header, then uses a trammel jig to cut siding and casing.

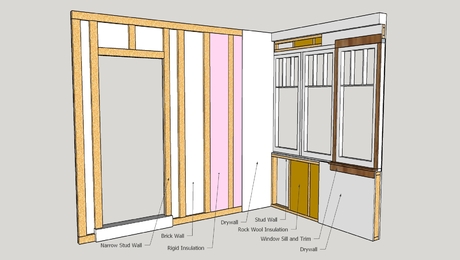

Synopsis: The author shows how he solves the unique framing and trim problems that come with arch-top windows, including header construction, flashing, and wall shingles.

Round-top, circle-top, or arch-top, whatever you call them, such windows have become a popular architectural feature. They add light and view and a touch of grandeur to a house. But these windows require carpenters to come up with some resourceful solutions when it comes to installation and trimming. Here, I’ll describe techniques that work for me, including some I used on a recent project in rural Hunterdon County, New Jersey.

Solving the structural problems

A typical rectangular window has a structural header at the top of the rough opening, and the header is supported by trimmer studs that pick up any loads above. This header—I usually use a doubled 2×10 with a 2×4 laid flat on the bottom—sits below the double top plates, which means the top of the window is about 13 in. below the ceiling.

With arch-top windows, however, it’s common to want the top of the window closer to the ceiling, which means there’s no room for a conventional header. Usually the arch top will stop 5 in. or 6 in. below the ceiling line, so that after installing the casing, you still have some clearance between the casing and the ceiling.

I use two methods to eliminate the conventional header. The first method is used if the window is in the first-floor wall of a two-story house. In this case, second-floor deck, wall, and roof loads must be supported. I move the header up above the top plate. In 2×4 framing, this would call for a double 2×10 with plywood sandwiched between; in 2×6 framing, it would call for a triple 2×10 within plywood. In either case, I use the rim joist as the outside layer of the header. If the ends of floor joists bear above windows, I then install metal hangers to support the joists that meet at the header.

I use a different method if the window is in a wall supporting only ceiling and roof loads, where we often have less depth to work with. I usually have room for a smaller-dimension header that’s beefed up to carry the roof loads. For window openings 3 ft. to 4 ft. wide, I use a piece of steel sandwiched between 2x6s, or a piece of steel angle (such as masons use for lintels) packed with two 2x4s. I bolt these headers together with carriage bolts.

RELATED STORIES

For more photos, drawings, and details, click the View PDF button below:

Fine Homebuilding Recommended Products

Fine Homebuilding receives a commission for items purchased through links on this site, including Amazon Associates and other affiliate advertising programs.

Anchor Bolt Marker

Smart String Line

Original Speed Square