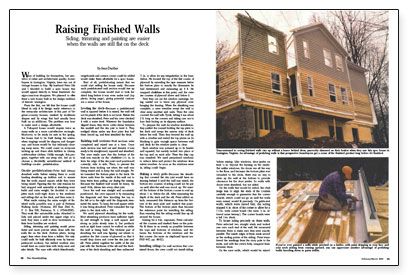

Raising Finished Walls

Siding, trimming and painting are easier when the walls are still flat on the deck.

Synopsis: Wood-framed walls are typically hoisted into place before windows, siding, and trim are installed. The author shows how the process can be reversed to save time and trouble and eliminate the hazards of working far off the ground on ladders or staging.

Wary of building for themselves, but sensitive to value and architectural quality, home-buyers in Lexington, Virginia, have run out of vintage houses to buy. My husband Peter Sils and I decided to build a spec house that would appeal directly to these frustrated, design-conscious shoppers. We planned to offer them a new house built in the design tradition of historic Lexington.

From the first, we felt that the house could blend in only if its design made reference to the vernacular architecture of this part of Virginia — country houses, marked by rectilinear shapes and by wings that had usually been built on as additions. The problem was how to make such a design affordable.

A T-shaped house would require twice as many walls as a more cost-effective rectangle. Moreover, to be ready for sale in the spring, the house had to be built during the winter, when stagings would be slippery and dangerous, and hours would be lost tediously clearing away snow. We could count on everyone inching up and down slick ladders in clumsy cold-weather clothes. Oddly enough, this program, together with our steep site, led us to choose a decidedly untraditional method of building — on-site prefabrication.

On-site prefabrication

Peter had always sheathed walls before raising them to avoid hauling sheathing up ladders and to ensure that the walls stayed square while they were being raised. Figuring that the only reasons he had stopped wall assembly at sheathing were habit and extra weight, he decided to complete each wall — right down to the windows and siding — flat on the deck, and then raise it.

What made raising the extra weight of finished walls possible was a pair of Hoitsma Walking Jacks (Hoitsma, Paterson, N. J.).They work like automobile jacks. Attached to 2x4s and placed under the upper edge of a wall, they raise a wall in slow increments as their lever handles are worked.

Siding, trimming and painting would prove faster and more precise when done with the walls flat on the deck than when done from a ladder. Not only could walls be built efficiently even by less-experienced workers, but skilled workers also would have an easier time with tricky eave and rake details. The ease with which friezeboards, vergeboards and cornice crown could be added would make them affordable for a spec house.

Best of all, prefabricating meant that we could start selling the house early. Because each prefabricated wall section would rise up complete, the house would start to look finished long before it was even under roof, giving potential customers a sense of the house.

For more photos, drawings, and details, click the View PDF button below:

Fine Homebuilding Recommended Products

Fine Homebuilding receives a commission for items purchased through links on this site, including Amazon Associates and other affiliate advertising programs.

Stabila Classic Level Set

Bluetooth Earmuffs

Magoog Tall Stair Gauges