I’ve been restoring a 120-year-old farmhouse that had 14-ft. 3×8 joists made of hemlock. Most of them were still sound, but their long, unsupported spans were pretty springy. My client didn’t like the bouncy feel of the floor, and I was concerned that the flex might cause some of the seams in the drywall to crack in the partition walls. Given the minimal clearance under the house and the excavation necessary to dig footings for a midspan beam, we decided to strengthen the existing joists. But with what? If we sistered a 2×8 onto each old joist, the lumber alone would cost about $1,300. As an alternative, we asked our lumberyard about the cost of ripping enough 3/4-in. plywood to serve the same purpose. Price for plywood plus cutting charge: $600.

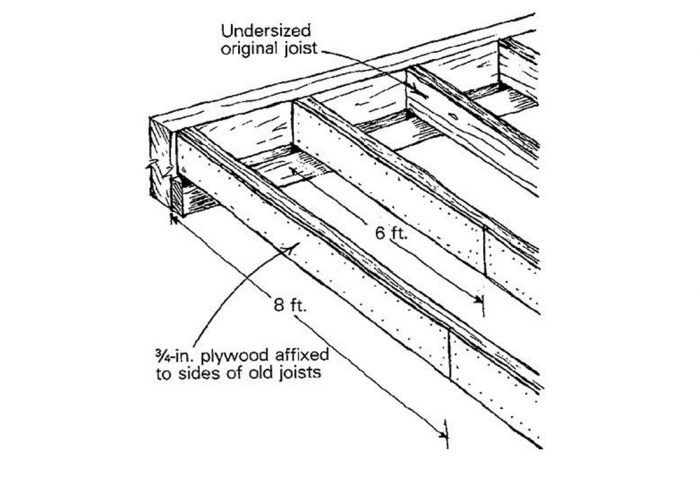

As shown in the drawing, we ended up going with the plywood method. We staggered the joints, and scabbed the plywood splints onto the sides of the old joists using liberal amounts of construction adhesive and 8d nails, driven with a nail gun. As we applied the adhesive to the joists, we also ran a bead of it along the top edge of the plywood. This helped to affix the subfloor to the plywood, and substantially cut down on floor squeaks. The result is a very stiff floor system.

—Richard E. Reed, Doylestown, PA

Edited and illustrated by Charles Miller

From Fine Homebuilding #62

View Comments

Great idea! For the same problem, we used 2 x 4s glued to the bottom of the old joist (with the 3 1/2" side flush with the old joist) ,bolted thru the 2 x 4 into the old joist with 5" lag bolts, and used joist hangers at the walls. Worked great, minimal cost.

Attaching the 2x4 with the 3 1/2" side vertical would give much more stiffness, but would be harder to attach.

Has anyone seen it done that way?

If so, how was the 2x4 attached?

What are some ideas for doing the attaching?

That is the way we did it, the 3 1/2" side is vertical, we used construction adhesive and 5" lag bolts with the holes predrilled, used joist hangers at the ends. The joist hangers just helped hold the 2 x 4 until the lag bolts went in. Lag bolts and washers.

The floor turned out much stiffer than it was before.

Except that 3/4 plywood only has 3/8 inch of the laminate running with the joist. The tip from ljg is much better. It is also much faster and considering the price of plywood where I live, much cheaper.

Sistering with ¾’’ plywood on both sides gives a shade less than 96% of the cross section of sistering with one 2x. This apparent near equivalency to sistering with 2x material is over optimistically deceiving. For one thing, as Suburbanguy points out, there is the issue of the direction of the laminates. For more details, take a look at the APA Design Manual for Plywood-Lumber Beams, which allows only parallel grain material to be used in calculating stiffness.

Another issue concerns the butt joints in the plywood. Unless the butt joints in the plywood are properly spliced, there will be a discontinuity in the plywood sister and that sister becomes ineffective in reducing springiness. Fortunately, Reed staggers the joints and thereby can count on one sister (instead of two) as being effective in reducing the springiness.

The bottom line is that the method shown for sistering with two ¾’’ plywood plates (instead of with one 2x) is roughly 25% as effective in reducing springiness. In other words, sistering with 2x material will double the stiffness of a joist. Sistering with plywood as shown in the tip will increase the stiffness by only about 25%. I’d say the savings of $700 was a pretty expensive savings.

The method described by ljg (attaching a bottom flange) has the potential of adding a lot more stiffness because the structural depth of the joist is increased and at the same time cross section area is added where it really counts – namely at the bottom extremity.

Both sistering and attaching a bottom flange have their own limitations. Sistering gets tough if there are lots of mechanical and electrical passing through the joists. Adding a bottom flange reduces headroom and can be a pain if there is lots of hanging M&E.

The discussion in this tip was limited to the problem of countering springiness. It isn’t unusual that a springy floor also has permanent sag that a client might also want to be rid of. That means jacking, and unless adding a supporting beam is practical, the stiffness of the joists needs to be increased enough to compensate for the jacking stress. (A sagged joist that has been jacked up is going to try to return to the sagged position when the jack is released.) In other words, eliminating the springiness isn’t necessarily going to eliminate sag.

What I’d like to see is a comprehensive floor joist stiffening manual written especially for builders. One of the key contents would be tables showing the effectiveness of various stiffening options. Other topics would be details, fastening methods and patterns, limitations, etc.. How about it FHB?

Great post CivEng43! A guide would be great, but of course anything with real values in it could be dicey for a publication like FHB to present; rather, I would like the Codes to address this with a matrix, not a performance-based set of formulas.

We had longer spans - 15' to 16' - installed circa 1830 or so - so we used matching LVLs, after jacking up the old beams to level - we had no subfloor so no glues - we needed to keep the old 15"-16" wide pine floor boards intact on their own.