Soon after I got into the hardwood-flooring business, I began to look for ways to set my floors apart from those of my competitors.One method that I have used with good results is decorative inlays of contrasting wood or metal. Inlay is a relatively easy and inexpensive way of dressing up what would other-wise be a rather ordinary wood floor.

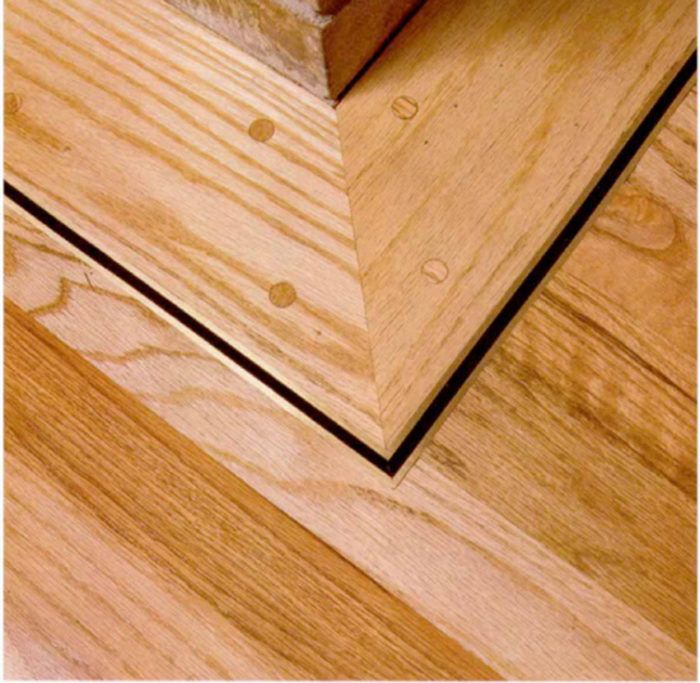

By definition, inlaying is the process of in-setting one material into another. Sometimesa groove or channel is created to house the inlay, but in my opinion, this method is notnearly as stable for floor use as is using aninlay material equal to the thickness of the finish flooring. In that sense, what I do is not strictly inlay, because I build the materials right into the floor as it’s being laid. Unlike traditional inlay, which is usually thinner thanthe host material, my inlay is as thick as the flooring itself.

One of my favorite techniques is to apply thin bands of metal and/or exotic wood to the edges of borders or headers. These thin lines of color contrast sharply with the surrounding flooring and are real eye-catchers. Another design popular333with clients is what I call the grid. This is a geometric pattern (frequently square or rectangular) of parquet flooring bordered by metal trim and inlaid into a regular plank or strip floor. The grid is a nice touch in an entry way or as an island in the middle of a kitchen or dining room.

Choosing materials—To make border inlay,first select the wood and metal you’d like touse. I prefer brass or aluminum because they’re soft, easy to cut and can usually be sanded without showing a lot of scratchingand without tearing up the sanding belts, asharder metals tend to do. Some caution is ad-vised here. Wood and metal have different coefficients of expansion and contraction. Wood moves as it picks up and gives off moisture,while metals change dimension with temperature changes. What this means is that metal inan inlaid floor will sometimes stand slightly above or below the wood surface, creating subtle ridges or grooves. There’s really no way to avoid this, and I’ve found that it’s usually not objectionable.

Buy bar stock about in. thick to in.thick and as wide as the flooring is thick. If you have to cut the bar stock, brass and alu-minum can be safely sawn on a band saw fit-ted with a metal cutting blade. Ebony, rose-wood, padauk, purple heart, walnut, cherry,mahogany and maple make nice inlay woods,although you could use any species with the color contrast you like. Saw the wood into strips that look good with the metal you in-tend to use.

For more detail and photos, click the View PDF button below.