The toughest part about pouring a concrete wall atop a rocky ledge is getting the forms to match the undulating surface of the rocks. A bad fit under these circumstances can mean a lot of lost concrete and some heavy messes to clean up. Faced with this challenge, we took our inspiration from a tool usually put to use by trim carpenters — the contour gauge (see drawing).

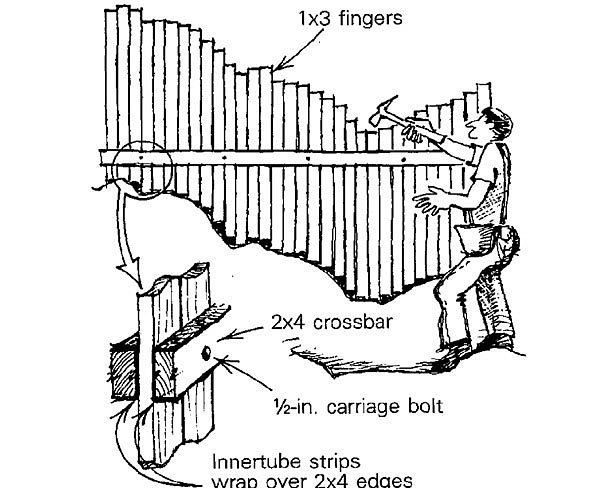

Like the smaller version, ours has individual fingers held in place by a crossbar. The fingers can be moved independently to mimic an uneven surface. But instead of tiny stainlesssteel pins, the fingers in our version are 1x3s. They are held in place by a pair of 2x4s, which are lined with innertube to keep the fingers from easily slipping. Five 1/2-in. carriage bolts hold the thing together.

To use the gauge, we adjusted the 2×4 crossbar so that it was level, and then tapped the fingers down until they touched the ledge. When all the fingers were touching the ground, we tightened the bolts to make sure they wouldn’t move. Then it was a simple matter to transfer the profile of the ground to our form plywood and cut out a perfect form — first time.

Dan Tishman, Damariscotta, ME